Page 634 - Tungaloy Catalog

P. 634

TAN type

TUNGAL O Y

Inserts

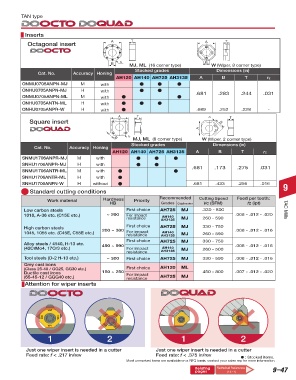

Octagonal insert A T A T

B rε MJ, ML (16 corner type) B W (Wiper, 8 corner type)

Stocked grades Dimensions (in)

Cat. No. Accuracy Honing

AH120 AH140 AH725 AH3135 A B T rε

ONMU0705ANPN-MJ M with

ONHU0705ANPN-MJ H with .681 .283 .244 .031

ONMU0705ANPN-ML M with

ONHU0705ANTN-ML H with

ONHU0705ANPR-W H with .689 .252 .228 -

A T rε T

Square insert B

A

TUNGAL O Y

rε

MJ, ML (8 corner type) W (Wiper, 2 corner type)

B

Stocked grades Dimensions (in)

Cat. No. Accuracy Honing

AH120 AH140 AH725 AH3135 A B T rε

SNMU1706ANPR-MJ M with

SNHU1706ANPR-MJ H with .681 .173 .275 .031

SNMU1706ANTR-ML M with

SNHU1706ANTR-ML H with

SNHU1706ANFN-W H without .681 .433 .256 .016 9

Standard cutting conditions

Recommended Cutting Speed Feed per tooth:

Work material Hardness Priority

HB Grades Chipbreaker Vc (SFM) fz (ipt)

Low carbon steels First choice AH725 MJ .330 - 800 TAC Mills

1018, A-36 etc. (C15E etc.) ~ 200 For impact AH140 .008 - .012 - .020

resistance AH3135 MJ 260 - 590

High carbon steels 200 ~ 300 First choice AH725 MJ 330 - 750 .008 - .012 - .016

1045, 1055 etc. (C45E, C55E etc.) For impact AH140 MJ

resistance AH3135 260 - 590

First choice AH725 MJ 330 - 750

Alloy steels / 4140, H-13 etc. 490 ~ 990 .008 - .012 - .016

(42CrMo4, 17Cr3 etc.) For impact AH140 MJ 260 - 500

resistance AH3135

Tool steels (D-2 H-13 etc.) ~ 300 First choice AH725 MJ 330 - 590 .008 - .012 - .016

Grey cast irons

(Class 25-40 / GG25, GG30 etc.) First choice AH120 ML

Ductile cast irons 150 ~ 250 For impact 450 - 800 .007 - .012 - .020

(65-45-12 / GGG40 etc.) resistance AH725 MJ

Attention for wiper inserts

TUNGAL O Y

1 2 1 2

Just one wiper insert is needed in a cutter Just one wiper insert is needed in a cutter

Feed rate: f < .217 in/rev Feed rate: f < .375 in/rev

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Relating Technical Reference 9–47

pages (14-1)