Page 638 - Tungaloy Catalog

P. 638

TUNGAL O Y

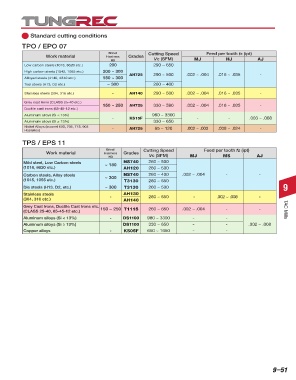

Standard cutting conditions

TPO / EPO 07

Brinell Cutting Speed Feed per tooth fz (ipt)

Work material Hardness Grades

HB Vc (SFM) MJ HJ AJ

Low carbon steels (1018, 8620 etc.) 200 290 ~ 650

High carbon steels (1045, 1055 etc.) 200 ~ 300

AH725 290 ~ 500 .002 ~ .004 .016 ~ .035 -

Alloyed steels (4140, 4340 etc.) 150 ~ 300

Tool steels (H13, D2 etc.) ~ 300 260 ~ 400

Stainless steels (304, 316 etc.) - AH140 290 ~ 500 .002 ~ .004 .016 ~ .035 -

Grey cast irons (CLASS 25-40 etc.)

150 ~ 250 AH725 330 ~ 590 .002 ~ .004 .016 ~ .035 -

Ductile cast irons (65-45-12 etc.)

Aluminum alloys (Si < 13%) 980 ~ 3300

- KS15F - - .003 ~ .008

Aluminum alloys (Si ≥ 13%) 330 ~ 650

Nickel Alloys (Inconel 600, 706, 718. 903 - 65 ~ 120 .002 ~ .003 .008 ~ .024 -

Hastelloy) AH725

TPS / EPS 11

Brinell Cutting Speed Feed per tooth fz (ipt)

Work material Hardness Grades

HB Vc (SFM) MJ MS AJ

Mild steel, Low Carbon steels ~ 180 NS740 260 ~ 500

(1018, 8620 etc.) AH120 260 ~ 500

Carbon steels, Alloy steels ~ 300 NS740 260 ~ 400 .002 ~ .004 - -

(1045, 1055 etc.) T3130 260 ~ 650

Die steels (H13. D2, etc.) ~ 300 T3130 260 ~ 500 9

Stainless steels - AH130 260 ~ 650 - .002 ~ .008 -

(304, 316 etc.) AH140

Grey Cast Irons, Ductile Cast Irons etc. 150 ~ 250 T1115 260 ~ 650 .002 ~ .004 - -

(CLASS 25-40, 65-45-12 etc.) TAC Mills

Aluminum alloys (Si < 13%) - DS1100 980 ~ 3300 - -

Aluminum alloys (Si ≥ 13%) DS1100 330 ~ 650 - - .002 ~ .008

Copper alloys - KS05F 650 ~ 1650 - -

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–51