Page 642 - Tungaloy Catalog

P. 642

18

TUNGAL O Y Steel Stainless Cast Iron Non-ferrous Super alloys

TPO / EPO 18

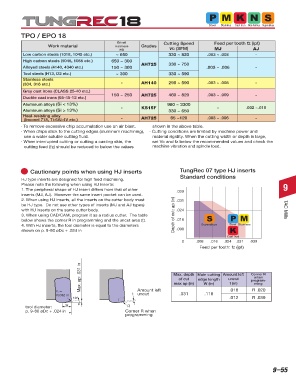

Brinell Cutting Speed Feed per tooth fz (ipt)

Work material Hardness Grades

HB Vc (SFM) MJ AJ

Low carbon steels (1018, 1045 etc.) ~ 650 330 ~ 820 .003 ~ .008 -

High carbon steels (1045, 1055 etc.) 650 ~ 300

AH725 330 ~ 750

Alloyed steels (4140, 4340 etc.) 150 ~ 300 .003 ~ .006 -

Tool steels (H13, D2 etc.) ~ 300 330 ~ 590

Stainless steels

(304, 316 etc.) - AH140 295 ~ 590 .003 ~ .008 -

Grey cast irons (CLASS 25-40 etc.)

150 ~ 250 AH725 460 ~ 820 .003 ~ .009 -

Ductile cast irons (65-45-12 etc.)

Aluminum alloys (Si < 13%) 980 ~ 3300

Aluminum alloys (Si ≥ 13%) - KS15F 330 ~ 650 - .002 ~.010

Heat-resisting alloy - 65 ~120 -

(Inconel 718, Ti-6Al-4V etc.) AH725 .003 ~ .006

· To remove excessive chip accumulation use an air blast. shown in the above table.

· When chips stick to the cutting edges (aluminum machining), · Cutting conditions are limited by machine power and

use a water soluble cutting fluid. material rigidity. When the cutting width or depth is large,

· When interrupted cutting or cutting a casting skin, the set Vc and fz below the recommended values and check the

cutting feed (fz) should be reduced to below the values machine vibration and spindle load.

Cautionary points when using HJ inserts TungRec 07 type HJ inserts

Standard conditions

HJ type inserts are designed for high feed machining.

Please note the following when using HJ inserts: 9

1. The peripheral shape of HJ insert differs from that of other .039

inserts (MJ, AJ). However the same insert pocket can be used.

2. When using HJ inserts, all the inserts on the cutter body must .031

be HJ type. Do not use other types of inserts (MJ and AJ types)

with HJ inserts on the same cutter body. .024 TAC Mills

3. When using CAD/CAM, program it as a radius cutter. The table Depth of cut: ap (in)

below shows the corner R in programming and the uncut area (t). .016

4. With HJ inserts, the tool diameter is equal to the diameters Superalloys Steel Stainless

shown on p. 9-80 øDc + .024 in .008

Cast Iron

0 .008 .016 .024 .031 .039

Feed per tooth: fz (ipt)

Max. ap: .031 in Max. depth Main cutting Amount left Corner R

when

uncut

of cut

edge length

program-

t (in)

max ap (in)

W (in)

ming

Amount left

rε = t uncut .031 .118 .016 R .020

R.032 in

10° .012 R .039

tool diameter: w R

p. 9-80 øDc + .024 in Corner R when

programming

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–55