Page 640 - Tungaloy Catalog

P. 640

17 90° Air Hole

TUNGAL O Y Steel Stainless Cast Iron Non-ferrous Super alloys

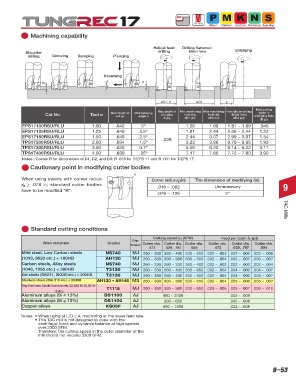

Machining capability

Helical feed Drilling flattened

Shoulder drilling blind hole Enlarging

milling Grooving Ramping Plunging

Traversing

ap θ A

øD1, 2 øD3 E

Max cutting

Max depth of Min. machining Max machining Hole dia. in drilling width in

Cat No. Tool ø Max Depth of Max ramping plunging hole dia. hole dia (blind hole) enlarging hole

angle θ

cut ap

A (in) øD1 (in)* øD2 (in)* øD3 (in)*

E (in)

EPS17100RSU/RLU 1.00 .642 5º 1.26 1.89 1.81 ~ 1.89 .945

EPS17125RSU/RLU 1.25 .640 3.5º 1.81 2.44 2.36 ~ 2.44 1.22

EPS17150RSU/RLU 1.50 .640 2.5º .039 2.44 3.07 2.99 ~ 3.07 1.54

TPS17200RSU/RLU 2.00 .634 1.5º 3.23 3.86 3.78 ~ 3.85 1.93

TPS17300RSU/RLU 3.00 .630 0.7º 5.59 6.22 6.14 ~ 6.22 3.11

TPS17400RSU/RLU 4.00 .630 .05º 7.17 7.80 7.72 ~ 7.80 3.90

Notes : Corner R for dimensions of D1, D2, and D3: R .016 for T/EPS 11 and R .031 for T/EPS 17.

Cautionary point in modifying cutter bodies

R

When using inserts with corner radius Corner radius r ε (in) The dimension of modifying (in)

r ε ≥ .078 in, standard cutter bodies .016 ~ .062 Unnecessary 9

have to be modified “R”.

.078 ~ .126 2” TAC Mills

Standard cutting conditions

Cutting speed vc (SFM) Feed per tooth fz (ipt)

Chip-

Work materials Grades Cutter dia. Cutter dia. Cutter dia. Cutter dia. Cutter dia. Cutter dia.

breaker

.472 .629, .787 .984 .472 .629, .787 .984

Mild steel, Low Carbon steels NS740 MJ 260 ~ 330 330 ~ 400 330 ~ 500 .002 ~ .003 .002 ~ .005 .002 ~ .006

(1018, 8620 etc.) < 180HB AH120 MJ 260 ~ 330 330 ~ 500 330 ~ 500 .002 ~ .004 .005 ~ .007 .005 ~ .007

Carbon steels, Alloy steels NS740 MJ 260 ~ 330 260 ~ 330 260 ~ 400 .002 ~ .003 .002 ~ .003 .002 ~ .004

(1045, 1055 etc.) < 300HB T3130 MJ 260 ~ 330 260 ~ 400 330 ~ 650 .002 ~ .004 .004 ~ .006 .004 ~ .007

Die steels (SKD11, SKD61etc.) < 300HB T3130 MJ 260 ~ 330 260 ~ 400 330 ~ 500 .002 ~ .004 .004 ~ .006 .005 ~ .007

Stainless steels (304, 316 etc.) < 250HB AH130 • AH140 MS 260 ~ 330 330 ~ 500 330 ~ 650 .002 ~ .004 .005 ~ .006 .005 ~ .007

Grey Cast irons, Ductile Cast irons etc. (CLASS 25-40, 65-45- T1115 MJ 260 ~ 330 330 ~ 500 330 ~ 650 .003 ~ .005 .005 ~ .007 .006 ~ .010

12 etc.)

Aluminum alloys (Si < 13%) DS1100 AJ 980 ~ 3300 .002 ~ .008

Aluminum alloys (Si ≥ 13%) DS1100 AJ 330 ~ 650 .002 ~ .008

Copper alloys KS05F AJ 650 ~ 1650 .002 ~ .008

Notes: • When using at L/D ≥ 4, machining at the lower feed rate.

• This TAC mill is not designed to cope with the

centrifugal force and dynamic balance at high speeds

over 3300 SFM.

Therefore, the cutting speed in the outer diameter of the

mill should not exceed 3300 SFM.

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–53