Page 650 - Tungaloy Catalog

P. 650

Screw-on type TAC Mills

T/EPW13

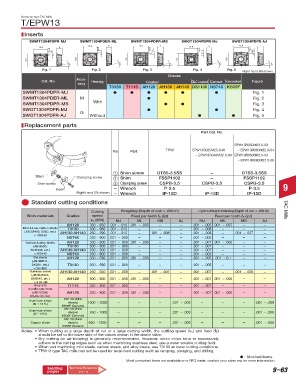

Inserts

SWMT1304PDPR-MJ SWMT1304PDER-ML SWMT1304PDPR-MS SWGT1304PDPR-MJ SWGT1304PDFR-AJ

13.6 5 13.6 5 5 13.6 5

13.6 5 13.6

rε0.8 rε0.8 rε0.8 rε0.8 rε0.0

1.4 1.4 1.4 1.4 .062

13.6 13.6 13.6 13.6 13.6

17˚ 17° 17° 17° 17°

Fig. 1 Fig. 2 Fig. 3 Fig. 4 Fig. 5

Right hand (R) shown.

Grades

Accu-

Cat. No. Honing Coated DLC coated Cermet Uncoated Figure

racy

T3130 T1115 AH120 AH130 AH140 DS1100 NS740 KS05F

SWMT1304PDPR-MJ d d d d d d Fig. 1

SWMT1304PDER-ML M d Fig. 2

SWMT1304PDPR-MS With d d Fig. 3

SWGT1304PDPR-MJ G d d Fig. 4

SWGT1304PDFR-AJ Without d d Fig. 5

Replacement parts

Part Cat. No.

EPW13R050M32.0-03

No Part TPW EPW13R025M25.0-01 ~ EPW13R080M32.0-04

~ EPW13R040M32.0-03 EPW13R050M32.0-04

~ EPW13R080M32.0-06

a Shim screw DTS5-3.5SS - DTS5-3.5SS

Shim Clamping screw b Shim FSSP1102 - FSSP1102

Shim

Clamping screw

Shim screw c Clamping screw CSPB-3.5 CSPB-3.5 CSPB-3.5

Shim screw

Insert Insert - Wrench P-3.5 - P-3.5 9

Right hand (R) shown. - Wrench IP-15D IP-15D IP-15D

Standard cutting conditions

Cutting Roughing (Depth of cut: > .039 in) Light cutting to finishing (Depth of cut: < .039 in) TAC Mills

Work materials Grades speed Feed per tooth fz (ipt) Feed per tooth fz (ipt)

vc (SFM) MJ ML MS AJ MJ ML MS AJ

AH120 330 ~ 850 .001 ~ .010 .001 ~ .008 - - .001 ~ .008 .001 ~ .007 - -

Mild & Low carbon steels T3130 500 ~ 980 .001 ~ .010 - - - .001 ~ .008 - - -

(JIS SS400, S25C, etc.) AH130·AH140 260 ~ 590 .001 ~ .010 - .001 ~ .008 - .001 ~ .008 - .001 ~ .007 -

< 180 HB

NS740 330 ~ 900 .001 ~ .006 - - - .001 ~ .005 - - -

Carbon & alloy steels AH120 330 ~ 800 .001 ~ .008 .001 ~ .006 - - .001 ~ .007 .001 ~ .005 - -

(JIS S50C, T3130 500 ~ 900 .001 ~ .008 - - - .001 ~ .007 - - -

SCM440, etc.) AH130·AH140 260 ~ 500 .001 ~ .008 - - - .001 ~ .007 - - -

< 300 HB NS740 330 ~ 800 .001 ~ .006 - - - .001 ~ .005 - - -

Die steels AH120 330 ~ 590 .001 ~ .006 .001 ~ .005 - - .001 ~ .005 .001 ~ 0.1 - -

(JIS SKD11,

SKD61, etc.) T3130 330 ~ 590 .001 ~ .006 - - - .001 ~ .005 - - -

< 30 HRC

Stainless steels AH130·AH140 260 ~ 650 .001 ~ .008 - .001 ~ .007 - .001 ~ .007 - .001 ~ .006 -

(JIS SUS304,

SUS316, etc.) AH120 500 ~ 800 .001 ~ .008 .001 ~ .006 - - .001 ~ .007 .001 ~ .005 - -

< 9.84 HB

Grey and T1115 330 ~ 800 .001 ~ .008 - - - .001 ~ .007 - - -

ductile cast Irons

(JIS FC250, AH120 330 ~ 800 .001 ~ .008 .001 ~ .006 - - .001 ~ .007 .001 ~ .005 - -

65-45-12, etc.)

DS1100 (First

Aluminum alloys

(Si < 13 %) choice) 1000 ~ 3300 - - - .001 ~ .008 - - - .001 ~ .008

KS05F (General)

DS1100 (First

Aluminum alloys

(Si ≥ 13%) choice) 260 ~ 1000 - - - .001 ~ .008 - - - .001 ~ .008

KS05F (General)

DS1100 (First

Copper alloys choice) 650 ~ 1650 - - - .001 ~ .008 - - - .001 ~ .008

KS05F (General

Notes: • When cutting at a large depth of cut or a large cutting width, the cutting speed (vc) and feed (fz)

should be set to the lower side of the values shown in the above table.

• Dry cutting (or air-blowing) is generally recommended. However, when chips tend to excessively

adhere to the cutting edges such as when machining stainless steel, use a water soluble cutting fluid.

• When wet machining mild steels, carbon steels, and alloy steels, use T3130 at lower cutting conditions.

• TPW13 type TAC mills can not be used for axial-feed cutting such as ramping, plunging, and drilling.

d : Stocked items.

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Relating Technical Reference 9–63

pages (14-1)