Page 654 - Tungaloy Catalog

P. 654

øDb

NEW ød a

b

R

Lf

ap

øDc

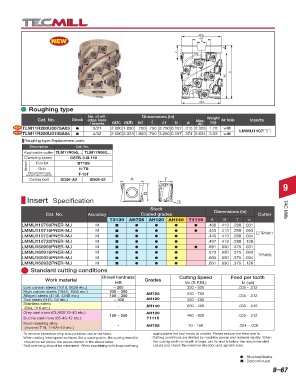

Roughing type

No. of eff. Dimensions (in)

Cat. No. Stock edge lines Max. Weight Air hole Inserts

/ inserts øDc øDb ød r Lf b a ap (kg)

NEW TLM11R200U0075A03 3/21 2.000 1.850 .750 .750 2.750 0.157 .315 2.303 1.78 with

NEW TLM11R250U0100A04 4/32 2.500 2.323 1.000 .750 3.250 0.197 .374 2.634 3.33 with LMMU1107uu

Air

Coolant

Cat. No. Stock No. of Dimensions (in) Weight hole Center bolt Inserts Roughing type: Replacement parts

Inserts

ØDc ØDb Ød r Lf b a (kg) Description Cat. No.

TPM11R200U0075A05 5 2.00 1.77 .750 .750 1.57 0.24 0.32 0.3 with (C0.375x1.125H) Applicable cutter TLM11R050… TLM11R063…

TPM11R250U0075A06 6 2.50 1.77 .750 .750 1.57 0.24 0.32 0.5 with (C0.375x1.125H) Clamping screw CSTB-3.5L110

LMMU1107uuPNER-MJ

TPM11R300U0100A06 6 3.00 2.17 1.00 .750 1.97 0.24 0.39 0.9 with (C0.500x1.375H) Torx bit BT15S

TPM11R400U0150A08 8 4.00 3.07 1.50 1.06 1.97 0.31 0.63 1.4 with (TMBA-0.750H) Wrench Grip H-TB

TPM16R300U0100A05 5 3.00 2.17 1.00 .750 1.97 0.24 0.39 1.0 with (C0.500x1.375H) substitution wrench T-15T

Mono block type

TPM16R400U0150A06 6 4.00 3.07 1.50 1.06 1.97 0.31 0.63 1.6 with (TMBA-0.750H) LMMU1609uuPNER-MJ Center bolt SD06-A2 SD08-52 A T

TPM16R500U0150A07 7 5.00 3.07 1.50 1.06 2.48 0.39 0.63 3.0 with (TMBA-0.750H) 9

TPM11R300U0100A08 8 3.00 2.17 1.00 .750 1.97 0.24 0.39 1.0 with (C0.500x1.375H)

LMMU1107uuPNER-MJ B

TPM11R400U0150A11 11 4.00 3.07 1.50 1.06 1.97 0.31 0.63 1.5 with (TMBA-0.750H)

Insert Specification rε

Stock TAC Mills

Cat. No. Accuracy Coated grades Dimensions (in) Cutter

T3130 AH725 AH120 AH140 T1115 A B T rε

LMMU110708PNER-MJ M .460 .413 .280 .031

LMMU110716PNER-MJ M .453 .413 .280 .063 E/TPM11

LMMU110724PNER-MJ M .445 .413 .280 .094

LMMU110732PNER-MJ M .437 .413 .280 .126

LMMU160908PNER-MJ M .681 .630 .375 .031

LMMU160916PNER-MJ M .673 .630 .375 .063

LMMU160924PNER-MJ M .665 .630 .375 .094 TPM16

LMMU160932PNER-MJ M .661 .630 .375 .126

Standard cutting conditions

Brinell hardness Cutting Speed Feed per tooth

Work material Grades

HB Vc (S.F.M.) fz (ipt)

Low carbon steels (1018, 8620 etc.) ~ 200 330 - 820 .005 - .012

High carbon steels (1045, 1055 etc.) 200 ~ 300 AH725 330 - 760

Alloyed steels (4140, 4340 etc.) 150 ~ 300 .005 - .012

Tool steels (H13, D2 etc.) ~ 300 AH120 330 - 590

Stainless steels - 200 - 460 .005 - .012

(304, 316 etc.) AH140

Grey cast irons (CLASS 25-40 etc.) AH120

150 ~ 250 460 - 820 .005 - .012

Ductile cast irons (65-45-12 etc.) T1115

Heat-resisting alloy

(Inconel 718, Ti-6Al-4V etc.) - AH725 70 - 160 .004 - .008

· To remove excessive chip accumulation use an air blast. applications the tool tends to chatter. Please reduce the feed rate fz.

· When cutting interrupted surfaces like a casting skin, the cutting feed (fz) · Cutting conditions are limited by machine power and material rigidity. When

should be set below the values shown in the above table. the cutting width or depth is large, set Vc and fz below the recommended

· Tool overhang should be minimized. When machining with long overhang values and check the machine vibration and spindle load.

: Stocked items.

: Discontinued

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–67