Page 652 - Tungaloy Catalog

P. 652

TPQ / EPQ type

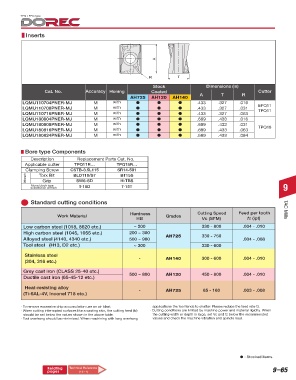

Inserts

A

R T

Stock Dimensions (in)

Cat. No. Accuracy Honing Coated Cutter

AH725 AH120 AH140 A T R

LQMU110704PNER-MJ M with d d d .433 .327 .016

LQMU110708PNER-MJ M with d d d .433 .327 .031 EPQ11

TPQ11

LQMU110716PNER-MJ M with d d d .433 .327 .063

LQMU180804PNER-MJ M with d d d .689 .433 .016

LQMU180808PNER-MJ M with d d d .689 .433 .031

LQMU180816PNER-MJ M with d d d .689 .433 .063 TPQ18

LQMU180824PNER-MJ M with d d d .689 .433 .094

Bore type Components

Description Replacement Parts Cat. No.

Applicable cutter TPQ11R… TPQ18R…

Clamping Screw CSTB-3.5L115 SR14-591

Wrench Torx Bit BLDT10/S7 BT15S

Grip

SW6-SD

H-TBS

Mono block type T-10D T-15T

substitution wrench 9

Standard cutting conditions

Work Material Hardness Grades Cutting Speed Feed per tooth TAC Mills

HB Vc (SFM) fz (ipt)

Low carbon steel (1018, 8620 etc.) ~ 200 330 - 800 .004 - .010

High carbon steel (1045, 1055 etc.) 200 ~ 300

Alloyed steel (4140, 4340 etc.) 500 ~ 980 AH725 330 - 750 .004 - .008

Tool steel (H13, D2 etc.) ~ 300 330 - 600

Stainless steel

(304, 316 etc.) - AH140 300 - 600 .004 - .010

Grey cast iron (CLASS 25-40 etc.)

Ductile cast iron (65-45-12 etc.) 500 ~ 800 AH120 450 - 800 .004 - .010

Heat-resisting alloy

(Ti-6AL-4V, Inconel 718 etc.) - AH725 65 - 160 .003 - .008

· To remove excessive chip accumulation use an air blast. applications the tool tends to chatter. Please reduce the feed rate fz.

· When cutting interrupted surfaces like a casting skin, the cutting feed (fz) · Cutting conditions are limited by machine power and material rigidity. When

should be set below the values shown in the above table. the cutting width or depth is large, set Vc and fz below the recommended

· Tool overhang should be minimized. When machining with long overhang values and check the machine vibration and spindle load.

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Relating Technical Reference 9–65

pages (14-1)