Page 658 - Tungaloy Catalog

P. 658

TAC Mills

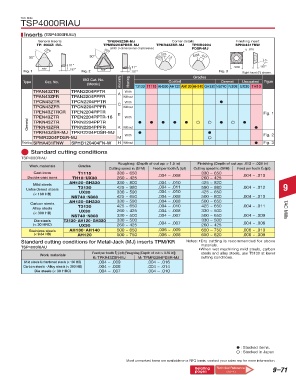

TSP4000RIAU

Inserts (TSP4000RIAU)

General inserts TPKR43ZSR-MJ Corner details Finishing insert

TPN43ZR/L TPMR2204PDSR-MJ TPKR43ZSR-MJ TPMR2204 SPHA431FNW

(With 3-dimensional chipbreaker) PDSR-MJ

.078 .059 r ε .016

.023

90° 90° .023 1.5 r ε 0.8 .047

11°

11° .187"

.500" .187" .500" 11° .500

Fig. 1 Fig. 2 .187" Fig. 3 Right hand (R) shown.

ISO Cat. No. Grades

Type Cat. No. Accuracy Honing Coated Cermet Uncoated Figure

(Metric) T3130 T1115 AH330 AH120 AH130 AH140 GH330 NS740 N308 UX30 TH10

TPAN43ZTR TPAN2204PPTR With

TPAN43ZFR TPAN2204PPFR A Without

TPCN43ZTR TPCN2204PPTR With d

TPCN43ZFR TPCN2204PPFR C Without

TPEN43ZTRCR TPEN2204PPTR Fig. 1

TPEN43ZTR TPEN2204PPTR-16 E With

General TPKN43ZTR TPKN2204PPTR K Without d d d d d d d d

TPKN2204PPFR

TPKN43ZFR

TPKR43ZSR-MJ TPKR2204PDSR-MJ d d

TPMR2204PDSR-MJ M With Fig. 2

Finishing SPHA431FNW SPHB120404FN-W H Without d Fig. 3

Standard cutting conditions

TSP4000RIAU

Roughing (Depth of cut ap: > 1.5 in) Finishing (Depth of cut ap: .012 ~ .028 in)

Work materials Grades

Cutting speed vc (SFM) Feed per tooth fz (ipt) Cutting speed vc (SFM) Feed per tooth fz (ipt)

Cast irons T1115 330 ~ 650 330 ~ 650

Ductile cast irons TH10 • UX30 260 ~ 425 .004 ~ .008 260 ~ 425 .004 ~ .010

AH120 • GH330 330 ~ 800 .004 ~ .010 425 ~ 820

Mild steels

Unhardened steels T3130 425 ~ 980 .004 ~ .011 590 ~ 980 .004 ~ .012 9

425 ~ 650

330 ~ 590

.004 ~ .010

(< 180 HB) UX30

NS740 • N308 425 ~ 650 .004 ~ .008 500 ~ 800 .004 ~ .010

AH120 • GH330 330 ~ 590 .004 ~ .008 500 ~ 650

Carbon steels 425 ~ 650 .004 ~ .010 425 ~ 650 .004 ~ .011

Alloy steels T3130 260 ~ 425 .004 ~ .008 330 ~ 500 TAC Mills

(< 300 HB) UX30

NS740 • N308 330 ~ 500 .004 ~ .007 500 ~ 650 .004 ~ .009

Die steels T3130 • AH120 • GH330 330 ~ 500 330 ~ 500

(< 30 HRC) UX30 260 ~ 425 .004 ~ .007 260 ~ 425 .004 ~ .008

Stainless steels AH130 • AH140 500 ~ 650 .006 ~ .009 650 ~ 750 .006 ~ .010

(< 9.84 HB) AH120 500 ~ 750 .006 ~ .008 650 ~ 820 .006 ~ .009

Standard cutting conditions for Metal-Jack (MJ) inserts TPM/KR Notes: • Dry cutting is recommended for above

materials.

TSP4000RIAU • When wet machining mild steels, carbon

Feed per tooth fz (ipt) (Roughing [Depth of cut: > 0.59 in]) steels and alloy steels, use T3130 at lower

Work materials

K: TPKR43ZSR-MJ M: TPMR2204PDSR-MJ cutting conditions.

Mild steels·Unhardened steels (< 180 HB) .004 ~ .009 .004 ~ .016

Carbon steels · Alloy steels (< 300 HB) .004 ~ .008 .004 ~ .014

Die steels (< 30 HRC) .004 ~ .007 .004 ~ .010

d : Stocked items.

: Stocked in Japan

d : Stocked items. : Stocked items.

: Stocked in Japan Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Relating Technical Reference 9–71

pages (14-1)