Page 660 - Tungaloy Catalog

P. 660

Super lightweight TAC Mills

T/EFE12

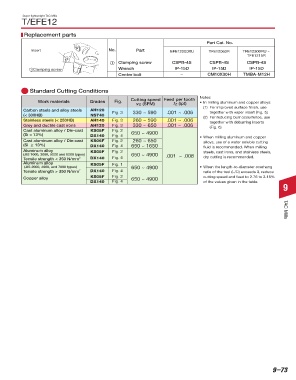

Replacement parts

Part Cat. No.

Insert No. Part EFE12200RU TFE12063R TFE12300RU ~

TFE1215R

a Clamping screw CSPB-4S CSPB-4S CSPB-4S

aClamping screw Wrench IP-15D IP-15D IP-15D

Center bolt - CM10X30H TMBA-M12H

Standard Cutting Conditions

Work materials Grades Fig. Cutting speed Feed per tooth Notes:

• In milling aluminum and copper alloys:

fz (ipt)

vc (SFM)

(1) For improved surface finish, use

Carbon steels and alloy steels AH120 Fig. 3 330 ~ 590 .001 ~ .006 together with wiper insert (Fig. 5)

(< 300HB) NS740 (2) For reducing burr occurrence, use

Stainless steels (< 250HB) AH140 Fig. 3 260 ~ 590 .001 ~ .006 together with deburring inserts

Grey and ductile cast irons AH120 Fig. 3 330 ~ 650 .001 ~ .006 (Fig. 6)

Cast aluminum alloy / Die-cast KS05F Fig. 2 650 ~ 4900

(Si < 13%) DX140 Fig. 4 • When milling aluminum and copper

Cast aluminum alloy / Die-cast KS05F Fig. 2 260 ~ 650 alloys, use of a water soluble cutting

(Si ≥ 13%) DX140 Fig. 4 650 ~ 1650 fluid is recommended. When milling

Aluminum alloy KS05F Fig. 2 steels, cast irons, and stainless steels,

(JIS 1000, 3000, 5000 and 6000 types) 650 ~ 4900 .001 ~ .008

Tensile strength < 350 N/mm 2 DX140 Fig. 4 dry cutting is recommended.

Aluminum alloy KS05F Fig. 1

(JIS 2000, 4000, and 7000 types) 650 ~ 4900 • When the length-to-diameter overhang

Tensile strength > 350 N/mm 2 DX140 Fig. 4 ratio of the tool (L/D) exceeds 3, reduce

Copper alloy KS05F Fig. 2 650 ~ 4900 cutting speed and feed to 2.76 to 3.15%

DX140 Fig. 4 of the values given in the table.

9

TAC Mills

Fig. 6

d : Stocked items. : Stocked items.

: Stocked in Japan Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–73