Page 664 - Tungaloy Catalog

P. 664

All PCD-tipped TAC Mills

DPD24

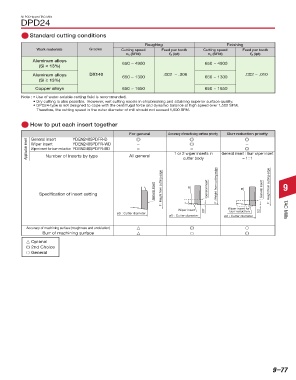

Standard cutting conditions

Roughing Finishing

Work materials Grades Cutting speed Feed per tooth Cutting speed Feed per tooth

vc (SFM) fz (ipt) vc (SFM) fz (ipt)

Aluminum alloys 650 ~ 4900 650 ~ 4900

(Si < 13%)

Aluminum alloys DX140 650 ~ 1300 .002 ~ .008 650 ~ 1300 .002 ~ .010

(Si ≥ 13%)

Copper alloys 650 ~ 1650 650 ~ 1650

Note : • Use of water-soluble cutting fluid is recommended.

• Dry cutting is also possible. However, wet cutting excels in chipbreaking and attaining superior surface quality.

• DPD24-type is not designed to cope with the centrifugal force and dynamic balance at high speed over 1,500 SFM.

Therefore, the cutting speed in the outer diameter of mill should not exceed 1,500 SFM.

How to put each insert together

For general Accuracy of machining surface priority Burr reduction priority

YDEN2405PDFR-D

General insert

Applicable insert Wiper insert YDEN2405PDFR-WD All general 1 or 2 wiper inserts in General insert : Burr wiper insert

-

-

-

Wiper insert for burr reduction YDEN2405PDFR-BD

-

Number of Inserts by type

= 1 : 1

cutter body

General insert F : Height from cutting edge R General insert F : Height from cutting edge R General insert F : Height from cutting edge 9

Specification of insert setting

Wiper insert .001 Wiper insert for TAC Mills

burr reduction

øD : Cutter diameter 0.2

øD : Cutter diameter øD : Cutter diameter

Accuracy of machining surface (roughness and undulation) n s

Burr of machining surface n s

n Optimal

2nd Choice

s General

: Stocked items.

: Stocked in Japan : Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–77