Page 885 - Tungaloy Catalog

P. 885

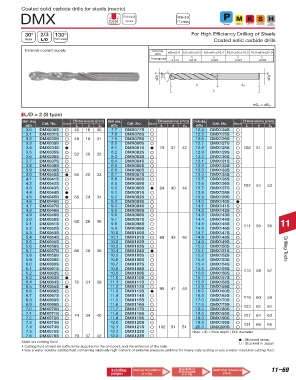

Coated solid carbide drills for steels (metric)

DMX External Ti (C,N,O) IT class Steel Stainless Cast Iron Superalloys Materials

IT9~10

Coated

Coolant

Hard

30° 2/3 130° For High Efficiency Drilling of Steels

Helix L/D Point angle Coated solid carbide drills

External coolant supply Drill Dia.

øDc øDc≤3.0 3.0<øDc≤6.0 6.0<øDc≤10.0 10.0<øDc≤18.0 18.0<øDc≤20.0

0

0

0

0

0

Tolerances −0.014 −0.018 −0.022 −0.027 −0.033

øDc h8 130° øDs h8

R R S

L

øDc = øDs

L/D = 2 (S type)

Drill dia. Stock Dimensions (mm) Drill dia. Stock Dimensions (mm) Drill dia. Stock Dimensions (mm)

øDs Cat. No. L R R s øDs Cat. No. L R R s øDs Cat. No. L R R s

3.0 DMX030S 46 16 30 7.7 DMX077S 12.4 DMX124S

3.1 DMX031S 7.8 DMX078S 12.5 DMX125S

3.2 DMX032S 49 18 31 7.9 DMX079S 12.6 DMX126S

3.3 DMX033S 8.0 DMX080S 12.7 DMX127S

3.4 DMX034S d 8.1 DMX081S d 79 37 42 12.8 DMX128S 102 51 51

3.5 DMX035S 52 20 32 8.2 DMX082S 12.9 DMX129S

3.6 DMX036S 8.3 DMX083S 13.0 DMX130S

3.7 DMX037S 8.4 DMX084S 13.1 DMX131S

3.8 DMX038S 8.5 DMX085S 13.2 DMX132S

3.9 DMX039S 8.6 DMX086S 13.3 DMX133S

4.0 DMX040S d 55 22 33 8.7 DMX087S 13.4 DMX134S

4.1 DMX041S 8.8 DMX088S 13.5 DMX135S

4.2 DMX042S 8.9 DMX089S 13.6 DMX136S 107 54 53

4.3 DMX043S 9.0 DMX090S d 84 40 44 13.7 DMX137S

4.4 DMX044S d 9.1 DMX091S 13.8 DMX138S

4.5 DMX045S d 58 24 34 9.2 DMX092S 13.9 DMX139S

4.6 DMX046S 9.3 DMX093S 14.0 DMX140S d

4.7 DMX047S 9.4 DMX094S 14.1 DMX141S

4.8 DMX048S 9.5 DMX095S 14.2 DMX142S

4.9 DMX049S 9.6 DMX096S 14.3 DMX143S

5.0 DMX050S 62 26 36 9.7 DMX097S 14.4 DMX144S

5.1 DMX051S 9.8 DMX098S 14.5 DMX145S 111 56 55 11

5.2 DMX052S 9.9 DMX099S 14.6 DMX146S

5.3 DMX053S 10.0 DMX100S 14.7 DMX147S

5.4 DMX054S 10.1 DMX101S 89 43 46 14.8 DMX148S

5.5 DMX055S 10.2 DMX102S 14.9 DMX149S

5.6 DMX056S 10.3 DMX103S 15.0 DMX150S

5.7 DMX057S 66 28 38 10.4 DMX104S d 15.1 DMX151S Drilling Tools

5.8 DMX058S 10.5 DMX105S 15.2 DMX152S

5.9 DMX059S 10.6 DMX106S 15.3 DMX153S

6.0 DMX060S 10.7 DMX107S 15.4 DMX154S

6.1 DMX061S 10.8 DMX108S 15.5 DMX155S 115 58 57

6.2 DMX062S 10.9 DMX109S 15.6 DMX156S

6.3 DMX063S d 11.0 DMX110S 15.7 DMX157S

6.4 DMX064S 70 31 39 11.1 DMX111S 15.8 DMX158S

6.5 DMX065S d 11.2 DMX112S 95 47 48 15.9 DMX159S

6.6 DMX066S 11.3 DMX113S d 16.0 DMX160S

6.7 DMX067S 11.4 DMX114S 16.5 DMX165S 119 60 59

6.8 DMX068S 11.5 DMX115S 17.0 DMX170S

6.9 DMX069S 11.6 DMX116S 17.5 DMX175S 123 62 61

7.0 DMX070S 11.7 DMX117S 18.0 DMX180S

7.1 DMX071S 74 34 40 11.8 DMX118S 18.5 DMX185S 127 64 63

7.2 DMX072S 11.9 DMX119S 19.0 DMX190S

7.3 DMX073S 12.0 DMX120S 19.5 DMX195S 131 66 65

7.4 DMX074S 12.1 DMX121S 102 51 51 20.0 DMX200S

7.5 DMX075S 12.2 DMX122S Note: L/D = Hole depth / Drill diameter

7.6 DMX076S 79 37 42 12.3 DMX123S

d : Stocked items.

Note on cutting fluid : Stocked in Japan

• Cutting fluid should be sufficiently supplied to the drill point and the entrance of the hole.

d : Stocked items • Use a water soluble cutting fluid containing relatively high content of extreme pressure additive for heavy duty cutting or use a water-insoluble cutting fluid.

Regrinding

Relating Cutting Conditions Procedures Technical reference 11–69

pages (11-70) (11-76) (14-1)