Page 459 - All Industrial Tool Supply | General Catalog

P. 459

ISCAR • Technical Turning

456

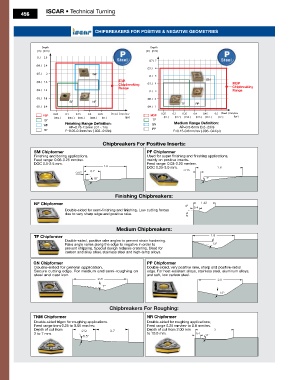

Chipbreakers For positive & Negative geometries

Depth Depth

[In) [mm) [In) [mm)

(1.) 2.8

(27.) 7

(09.) 2.4

(23.) 6

(07.) 2 WF

(2.) 5

(06.) 1.6 F3P (15.) 4 GN M3P

Chipbreaking

Range Chipbreaking

(04.) 1.2 (1.) 3 Range

(03.) 0.8 (08.) 2

SF NF TF PP

(01.) 0.4 (04.) 1

[Feed [mm/rev

F3P 0.05 0.1 (004.) 0.15 0.2 (008.) 0.25 (01.) [Feed [mm/rev M3P 0.25 (01.) 0.3 (012.) 0.35 0.4 (016.) 0.45 (018.) 0.5 (02.) (Ipr)

(Ipr)

(014.)

(006.)

(002.)

SF TF

WF Finishing Range Definition: GN Medium Range Definition:

AP=0.25-2.5mm (.01 -.1in)

AP=0.5-6mm (0.2-.23in)

NF F=0.05-0.3mm/rev (.002-.012in) PP F=0.15-0.6mm/rev (.006-.024ipr)

Chipbreakers For Positive Inserts:

SM Chipformer PF Chipformer

Finishing and boring applications. Used for super finishing and finishing applications,

Feed range: 0.06-0.25 mm/rev. mainly on positive inserts.

DOC 0.5-2.5 mm. Feed range: 0.03-0.20 mm/rev.

1.8 DOC 0.25-3.0 mm. 1.6

0.07 0.7 0.15

18˚ 7˚

Finishing Chipbreakers:

NF Chipformerp 4º 1.42

Double-sided for semi-finishing and finishing. Low cutting forces 0.4

due to very sharp edge and positive rake.

Medium Chipbreakers:

TF ChipformerCp o e

Double-sided, positive rake angles to prevent strain hardening.

Rake angle varies along the edge to negative in order to

prevent chipping. Special design reduces cratering. Used for

carbon and alloy steel, stainless steel and high-temp alloys.

GN Chipformer PP Chipformer

Double-sided for general application. Double-sided, very positive rake, sharp and positive-radial

Secure cutting edge. For medium and semi-roughing on edge. For heat-resistant alloys, stainless steel, aluminum alloys,

steel and cast iron. and soft, low carbon steel.

Chipbreakers For Roughing:

TNM Chipformer NR Chipformer

Double-sided trigon for roughing applications. Double-sided for roughing applications;

Feed range from 0.25 to 0.65 mm/rev. Feed range 0.25 mm/rev to 0.8 mm/rev.

Depth of cut from 2.9 3.7 Depth of cut from 2.00 mm 3

2 to 7 mm. to 10.0 mm. 0.4 11˚

8.5˚