Page 614 - All Industrial Tool Supply | General Catalog

P. 614

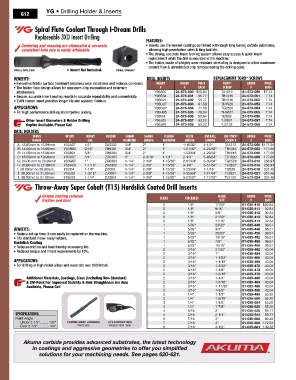

YG • Drilling Holder & Inserts

612

Spiral Flute Coolant Through I-Dream Drills

Replaceable 3XD Insert Drilling

feAtures:

Centering and reaming are eliminated & accurate, • Inserts use the newest coatings combined with tough long lasting carbide substrates,

consistent hole size is easily attainable allowing high penetration rates & long tool life.

• The strong, accurate insert locking system allows easy access & quick insert

replacement while the drill is mounted in the machine.

• The holder, made of a highly wear resistant steel alloy, is designed to allow maximum

coolant flow & unrestricted chip removal during the drilling cycle.

Drill HolDer ♦ Insert Not Included. Drill insert

Benefits: DrIll InSerTS replACemenT Torx SCrewS

®

• Innovative holder surface treatment improves wear resistance and reduces corrosion. InSerT orDer prICe Torx ® orDer prICe

• The holder flute design allows for maximum chip evacuation and minimum # # eACH SCrew # eACH

interference. Y03A07 24-573-030 $55.04 TA1213 24-573-050 $7.74

• Secure, accurate insert seating results in accurate repeatability and concentricity. Y03B04 24-573-031 55.77 TB1415 24-573-051 7.74

• TiAlN coated insert provides longer life and superior finishes. Y03B21 24-573-032 55.77 TB1516 24-573-052 7.74

Y03D07 24-573-033 61.58 TD1920 24-573-053 7.74

APPLiCAtiOns: Y03G07 24-573-034 77.19 TG2526 24-573-054 7.74

• For high performance drilling at competive pricing. Y03H05 24-573-035 79.34 TH2627 24-573-055 7.74

Y03I04 24-573-036 80.94 TI2829 24-573-056 7.74

Other Insert Diameters & Holder Drilling Y03J02 24-573-037 83.22 TJ2831 24-573-057 7.74

Depths Available, Please Call Y03J08 24-573-038 83.22 TJ3132 24-573-058 7.74

DrIll HolDerS

SerIeS InSerT InSerT HolDer SHAnk SHAnk FlAnge FluTe overAll uSe Torx ® orDer prICe

rAnge # o.D. # DIAmeTer lengTH DIAmeTer lengTH lengTH SCrew # # eACH

A: 12.00mm to 13.99mm Y03A07 1/2" ZA0302 3/4" 2" 1" 1-15/32" 4-1/2" TA1213 24-573-000 $177.56

B: 14.00mm to 15.99mm Y03B04 9/16" ZB0301 3/4" 2" 1" 1-21/32" 4-23/32" TB1415 24-573-003 177.56

B: 14.00mm to 15.99mm Y03B21 5/8" ZB0304 3/4" 2" 1" 1-53/64" 4-29/32" TB1516 24-573-006 177.56

D: 18.00mm to 19.99mm Y03D07 3/4" ZD0303 1" 2-3/16" 1-1/4" 2-1/4" 5-43/64" TD1920 24-573-009 177.80

G: 24.00 mm to 29.99mm Y03G07 1" ZG0303 1-1/4" 2-3/8" 1-15/32" 2-61/64" 6-39/64" TG2526 24-573-012 256.97

H: 26.00mm to 27.99mm Y03H05 1-1/16" ZH0302 1-1/4" 2-3/8" 1-15/32" 3-1/8" 6-51/64" TH2627 24-573-015 256.97

I: 28.00mm to 29.99mm Y03I04 1-1/8" ZI0302 1-1/4" 2-3/8" 1-15/32" 3-23/64" 7-1/16" TI2829 24-573-018 337.46

J: 30.00mm to 31.99mm Y03J02 1-3/16" ZJ0301 1-1/4" 2-3/8" 1-15/32" 3-35/64" 7-21/64" TJ2831 24-573-021 337.46

J: 30.00mm to 31.99mm Y03J08 1-1/4" ZJ0304 1-1/4" 2-3/8" 1-15/32" 3-23/32" 7-17/32" TJ3132 24-573-024 337.46

Throw-Away Super Cobalt (T15) Hardslick Coated Drill Inserts

Unique coating reduces BlADe orDer prICe

friction and heat SerIeS THICkneSS SIze # eACH

0 1/8" 17/32" 01-035-410 $32.84

0 1/8" 9/16" 01-035-411 32.84

0 1/8" 5/8" 01-035-412 32.84

0 1/8" 21/32" 01-035-413 32.84

0 1/8" 11/16" 01-035-414 32.84

1 5/32" 23/32" 01-035-446 36.51

Benefits: 1 5/32" 3/4" 01-035-448 36.51

• Reduce set-up time; it can easily be replaced on the machine. 1 5/32" 25/32" 01-035-450 36.51

• Fits standard throw-away holders. 1 5/32" 13/16" 01-035-452 36.51

Hardslick Coating 1 5/32" 7/8" 01-035-456 36.51

• Reduces friction and heat thereby increasing life. 1 5/32" 15/16" 01-035-460 36.51

• Reduces torque and thrust requirements by 10%. 2 3/16" 31/32" 01-035-462 43.04

2 3/16" 1" 01-035-464 43.04

2 3/16" 1-1/32" 01-035-466 43.04

APPLiCAtiOns: 2 3/16" 1-1/16" 01-035-468 43.04

• For drilling in high nickel alloys and materials over 280 Brinell. 2 3/16" 1-3/32" 01-035-470 43.04

2 3/16" 1-1/8" 01-035-472 43.04

2 3/16" 1-3/16" 01-035-476 43.04

Additional Materials, Coatings, Sizes (Including Non-Standard) 2 3/16" 1-1/4" 01-035-480 43.04

& SM-Point For Improved Stability & Hole Straightness Are Also 2 3/16" 1-5/16" 01-035-484 43.04

Available, Please Call 2 3/16" 1-11/32" 01-035-486 43.04

2 3/16" 1-3/8" 01-035-488 43.04

3 1/4" 1-1/2" 01-035-496 55.20

3 1/4" 1-9/16" 01-035-500 55.20

3 1/4" 1-5/8" 01-035-504 55.20

3 1/4" 1-7/8" 01-035-520 55.20

4 5/16 2" 01-035-528 69.77

SpeCIFICATIonS: 4 5/16 2-1/4" 01-035-544 69.77

Point Angle 5 7/16 3" 01-035-602 82.45

Under 2-1/2" ......... 132° tHrow-away HolDers eye protection 7 7/16 4" 01-035-668 112.53

Over 2-1/2" ........... 144° PAGE 605 PAGEs 1594-1600 8 7/16" 4-1/2" 01-035-684 149.38

Akuma carbide provides advanced substrates, the latest technology

in coatings and aggressive geometries to offer you simplified

solutions for your machining needs. See pages 620-621.