Page 618 - All Industrial Tool Supply | General Catalog

P. 618

TTC PRODUCTION • Technical Turning

616

Carbide Turning inserT grade informaTion

CARBIDE GRADE APPLICATIONS: CERMET GRADE APPLICATIONS:

GRADE C2 GRADE CT20

Uncoated grade mainly designed for the machining of cast iron materials at General cutting for turning. Finishing for milling.

medium speed. Suitable also for hardened steel, non-ferrous metals, plastic, Density (g/cm3), 7.1. hardness (HRA) 92.8. TRS (kg/mm2) 170.

rubber and wood. (Range of application ISO K20-K30) Cutting conditions (Steel):

GRADE C6 V = 50m/min. ~ 200m/min.

Uncoated grade developed for turning. Recommended for general use at F = +.05mm/rev. ~ -.40mm/rev.

moderate speed in steels, alloyed steels, malleable cast iron with long chips. B TYPE CHIPBREAKER

Might be used for light milling of mild steel. (Range of application ISO P20-P30) General purpose (light to medium cutting) with strong cutting edges.

GRADE TiC-65 (C5-C6) COATED Double sided chipbreaker with excellent chip control. Exclusively used for

Coated turning grade TiC-TiN, total coating thickness approximately 0.00025" cermet inserts.

on a tougher wear resistant substrate. Recommended for general use at KA TYPE CHIPBREAKER

moderate speed in carbon steel, tool steels, alloyed steels, cast steels, Light cutting for finishing. Excellent surface finish. Double sided chipbreaker

stainless steels. (Range of application ISO P20-P40/M25-M40) with excellent chip control.

GRADE KT150 (C2-C3/C7) TRIPLE COATED NO CHIPBREAKER

Triple coated turning grade, TiC-Al2O3-TiN, total coating thickness Single sided.

approximately 0.0004" on a highly wear resistant substrate. Recommended for

finishing and light roughing of steel, steel castings and cast iron at high speed

with low to medium feed rates. High wear resistance and good resistance to CERAMIC GRADE APPLICATIONS:

plastic deformation because of the alumina thermal barrier. For application with GRADE AW20

high demand on productivity. (Range of application ISO P05-P20/K05-K20) Composition Al2O3 - A hot isostatically pressed alumina material

GRADE KT300 (white ceramic) mainly applicable for roughing & finishing cast iron & steel in

Titanium nitride coating, gold color for carbon steels, tool steels, alloy steels, higher surface speed operations. This new process produces inserts that are

steel casting, malleable cast iron, austenitic and martensitic stainless steel, finer grained, denser, harder, have higher transverse rupture & impact

free-cutting steels. strengths, are less apt to chip or crack under mechanical or thermal shock &

are excellent in wear & crater resistance.

GRADE AB30

COATED CHIPBREAKER GRADES (NOT TRIPLE COATED): Composition Al2O3 - Our standard black ceramic is a composite with an

KT110 (K05 - K15) alumina matrix containing titanium carbide with excellent wear, crater &

Specially designed high wear resistant substrate. Thick layer of ceramic strength characteristics.

coating. Fine grain of ceramic coating. Excellent wear resistance. Reduced

chipping. High speed cutting of cast iron and steel. Longer tool life.

Stable cutting. Cost saving. Improved productivity. CHIPBREAKER GRADE COMPARISON GUIDE:

KT150 (K05 - K20) (P05 - P20) GRADE KENNAMETAL SANDVIK SECO SUMITOMO

Coated with excellent alumina and TiN heat resistant coating on a highly wear KT110 KC910, KC9010 GC3015 TP05, TP100 AC05, AC105, AC110

resistant substrate. For medium to high speed turning of steel and cast iron. KT150 KC990 GC4015 TP10 AC05A

KT210 (K10 - K30) KT210 KC950 GC4025 TP20 AC105, AC110G

Coated with multi-layer alumina and TiN on a tough, highly wear resistant KT250 KC9025, KC950 GC4025 TP15, TP25 AC108, AC2000

substrate. For general turning and interrupted cutting of cast iron. KT350 KC935 GC4035 TP30 AC15

KT250 (P10 - P30) KT450 KC850, KC9040 GC235 TP40 AC25

A good combination of high toughness substrate and excellent wear & heat

resistant alumina and TiN coating. For general turning of steels under medium

cutting conditions.

KT350 (P20 - P40) (M10-M30) CHIPBREAKER & GRADE GUIDE:

Improved edge strength with combination of high toughness substrate and APPLICATION CHIPBREAKER COATED GRADE (MATERIAL)

TiCN base multi-coated layer. For turning of steels and stainless steel at Finishing 33 KT110 (Cast Iron & Steel)

medium to heavy cutting conditions. Finishing to Medium Cutting 44 KT150 (Cast Iron & Steel)

KT450 (P25 - P45) (M20-M40) Medium Cutting 55 KT210 (Cast Iron), KT250 (Steel)

High toughness grade with combination of multi-coated TiN and specially Medium Cutting to Roughing MH KT350 (Steel, Stainless Steel)

designed substrate. For ro ughing or interrupted cutting of steels. Heavy Roughing KH KT450 (Steel, Stainless Steel)

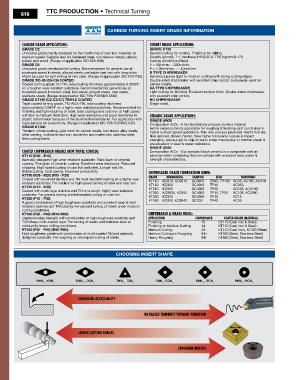

Choosing inserT shape