Page 623 - All Industrial Tool Supply | General Catalog

P. 623

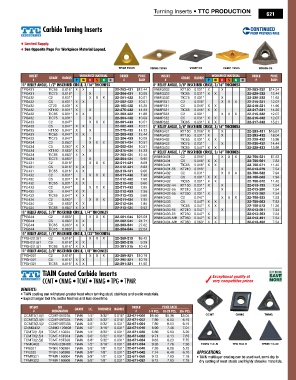

Turning Inserts • TTC PRODUCTION

621

Carbide Turning Inserts

♦ Limited Supply.

♦ See Opposite Page For Workpiece Material Legend.

TPGB TIC65 VNMG TIC65 VNMP C5 VNMP TIC65 WNMG C5

InserT Grade radIus WorkpIeCe MaTerIal order prICe InserT Grade radIus WorkpIeCe MaTerIal order prICe

# p M k s n h # eaCh # p M k s n h # eaCh

11° relIef anGle, 1/2" InsCrIbed CIrCle, 3/16" ThICkness 0° relIef anGle, 3/8" InsCrIbed CIrCle, 3/16" ThICkness

TPG431 TIC65 0.016" X X 22-203-431 $12.44 VNMG332 KT150 0.031" X X 22-283-332 $14.34

TPG431 TIC75 0.016" X 22-204-431 10.09 VNMG332 TIC65 0.031" X X 22-229-332 12.44

TPG432 C2 0.031" X X X 22-001-432 10.01 VNMG332 TIC75 0.031" X 22-230-332 11.63

TPG432 C5 0.031" X X 22-002-432 10.01 VNMP331 C2 0.016" X X X 22-215-331 12.07

TPG432 CT20 0.031" X 22-100-432 15.26 VNMP331 C5 0.016" X X 22-216-331 11.90

TPG432 KT150 0.031" X X 22-275-432 14.33 VNMP331 TIC65 0.016" X X 22-217-331 14.20

TPG432 TIC65 0.031" X X 22-203-432 11.86 VNMP332 C2 0.031" X X X 22-215-332 12.07

TPG432 TIC75 0.031" X 22-204-432 10.09 VNMP332 C5 0.031" X X 22-216-332 12.07

TPG433 C2 0.047" X X X 22-001-433 10.51 VNMP332 TIC65 0.031" X X 22-217-332 15.21

TPG433 C5 0.047" X X 22-002-433 10.51 0° relIef anGle, 3/8" InsCrIbed CIrCle, 3/16" ThICkness

TPG433 KT150 0.047" X X 22-275-433 14.33 VNMG431 KT150 0.016" X X 22-283-431 $16.67

TPG433 TIC65 0.047" X X 22-203-433 12.44 VNMG432 KT150 0.031" X X 22-283-432 18.04

TPG433 TIC75 0.047" X 22-204-433 10.09 VNMG432 TIC65 0.031" X X 22-229-432 15.98

TPG434 C2 0.063" X X X 22-001-434 10.51 VNMG432 TIC75 0.031" X 22-230-432 14.44

TPG434 C5 0.063" X X 22-002-434 10.51 VNMG433 TIC65 0.047" X X 22-229-433 15.98

TPG434 KT150 0.063" X X 22-275-434 14.33 0° relIef anGle, 1/2" InsCrIbed CIrCle, 3/16" ThICkness

TPG434 TIC65 0.063" X X 22-203-434 12.44 WNMG431 C2 0.016" X X X 22-700-531 $7.83

TPG434 TIC75 0.063" X 22-204-434 9.95 WNMG431 C5 0.016" X X 22-700-561 7.83

TPU431 C2 0.016" X X X 22-011-431 8.68 WNMG431 TIC65 0.016" X X 22-700-571 11.42

TPU431 C5 0.016" X X 22-012-431 8.82 22-013-279

TPU431 TIC65 0.016" X X 22-213-431 9.66 WNMG431-55 KT210 0.016" X X X 22-700-532 7.54

0.031"

X

C2

7.94

WNMG432

TPU432 C2 0.031" X X X 22-011-432 7.96 WNMG432 C5 0.031" X X 22-700-562 7.94

TPU432 C5 0.031" X X 22-012-432 7.96 WNMG432 TIC65 0.031" X X 22-700-572 11.42

TPU432 TIC65 0.031" X X 22-213-432 9.66 WNMG432-44 KT150 0.031" X X 22-013-153 7.54

TPU433 C2 0.047" X X X 22-011-433 7.85 22-013-280

TPU433 C5 0.047" X X 22-012-433 7.96 WNMG432-55 KT210 0.031" X X 22-013-382 7.54

0.031"

KT250

7.54

WNMG432-55

TPU433 TIC65 0.047" X X 22-213-433 9.66 WNMG433 C2 0.047" X X X 22-700-533 7.83

TPU434 C2 0.063" X X X 22-011-434 7.85 WNMG433 C5 0.047" X X 22-700-563 7.83

TPU434 C5 0.063" X X 22-012-434 7.85 WNMG433 TIC65 0.047" X X 22-700-573 11.26

TPU434 TIC65 0.063" X X 22-213-434 9.52 22-013-281

11° relIef anGle, 5/8" InsCrIbed CIrCle, 1/4" ThICkness WNMG433-55 KT210 0.047" X X 22-013-383 7.54

7.54

0.047"

KT250

WNMG433-55

TPG544 C2 0.063" X X X 22-001-544 $25.08 WNMG433-MH KT350 0.047" X X 22-013-491 7.54

TPG544 C5 0.063" X X 22-002-544 24.71 WNMG434-MH KT350 0.063" X X 22-013-492 7.54

TPG544 TIC65 0.063" X X 22-203-544 27.62

TPG544 TIC75 0.063" X 22-204-544 22.54

11° relIef anGle, 1/4" InsCrIbed CIrCle, 3/32" ThICkness

TPGH2(1.5)1 C2 0.016" X X X 22-289-215 $9.43

TPGH2(1.5)1 C5 0.016" X X 22-290-215 9.29

TPGH2(1.5)1 TIC65 0.016" X X 22-291-215 10.43

11° relIef anGle, 3/8" InsCrIbed CIrCle, 1/8" ThICkness

TPGH321 C2 0.016" X X X 22-289-321 $10.79

TPGH321 C5 0.016" X X 22-290-321 10.79

TPGH321 TIC65 0.016" X X 22-291-321 11.80

Tialn Coated Carbide Inserts Exceptional quality at

CCMT • CNMG • TCMT • TNMG • TPG • TPMR very competitive prices

Benefits:

• TiAlN coating can withstand greater heat when turning steel, stainless and exotic materials.

• Expect longer tool life, better finishes and less downtime.

InserT Iso Grade I.C. ThICkness radIus order _______prICe eaCh_______

# desIGnaTon # 1-9 pCs. 10-29 pCs. 30+ pCs.

CCMT2(1.5)1 CCMT-060204 TiAlN 1/4" 3/32" 0.016" 22-671-000 $6.40 $5.36 $5.04 CCMT CNMG TNMG

CCMT3(2.5)1 CCMT-09T304 TiAlN 3/8" 5/32" 0.016" 22-671-002 7.80 6.53 6.15

CCMT3(2.5)2 CCMT-09T308 TiAlN 3/8" 5/32" 0.031" 22-671-004 7.80 6.53 6.15

CNMG432 CNMG 120408 TiAlN 1/2" 3/16" 0.031" 22-671-010 8.90 7.46 7.01

TCMT2(1.5)1 TCMT-110204 TiAlN 1/4" 3/32" 0.031" 22-671-020 6.60 5.53 5.20

TCMT3(2.5)1 TCMT-16T304 TiAlN 3/8" 5/32" 0.031" 22-671-022 9.71 8.13 7.65

TCMT3(2.5)2 TCMT-16T308 TiAlN 3/8" 5/32" 0.031" 22-671-024 9.83 8.23 7.75

TNMG432 TNMG 220408 TiAlN 1/2" 3/16" 0.031" 22-671-034 9.26 7.76 7.30 TNMG TIALN TPG TIALN TPMR TIALN

TPG321 TPGN 160304 TiAlN 3/8" 1/8" 0.031" 22-671-040 7.26 6.08 5.72

TPG322 TPGN 160308 TiAlN 3/8" 1/8" 0.031" 22-671-042 7.74 6.48 6.10 APPLiCAtiOns:

TPMR321 TPMR 160304 TiAlN 3/8" 1/8" 0.031" 22-671-050 9.12 7.63 7.18 • TiAlN multilayer coating can be used wet, semi-dry to

TPMR322 TPMR 160308 TiAlN 3/8" 1/8" 0.031" 22-671-052 9.12 7.63 7.18 dry cutting of most steels and highly abrasive materials.