Page 1398 - Ceratizit Catalog

P. 1398

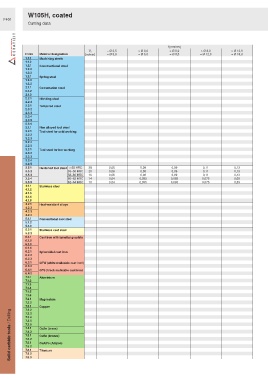

W105H, coated

F401

Cutting data

f [mm/rev]

= Ø 2,5 > Ø 3,0 > Ø 5,0 > Ø 8,0 > Ø 12,0

V c

Index Material designation [m/min] = Ø 3,0 = Ø 5,0 = Ø 8,0 = Ø 12,0 = Ø 16,0

1.1.1 Machining steels

1.1.2

1.2.1 Constructional steel

1.2.2

1.2.3

1.3.1 Spring steel

1.3.2

1.3.3

2.1.1 Cementation steel

2.1.2

2.1.3

2.2.1 Nitriding steel

2.2.2

2.3.1 Tempered steel

2.3.2

2.3.3

2.3.4

2.3.5

2.3.6

3.1.1 Non alloyed tool steel

3.2.1 Tool steel for cold working

3.2.2

3.2.3

3.2.4

3.2.5

3.3.1 Tool steel for hot working

3.3.2

3.3.3

3.3.4

3.3.5

3.5.1 Hardened tool steel < 55 HRC 28 0,06 0,08 0,09 0,11 0,13

3.5.2 55–58 HRC 20 0,06 0,08 0,09 0,11 0,13

3.5.3 58–60 HRC 16 0,06 0,08 0,09 0,11 0,13

3.5.4 60–62 HRC 14 0,04 0,055 0,065 0,075 0,09

3.5.5 62–64 HRC 10 0,04 0,055 0,065 0,075 0,09

4.1.1 Stainless steel

4.1.2

4.1.3

4.1.4

4.1.5

4.2.1 Heat-resistant alloys

4.2.2

4.2.3

4.2.4

5.1.1 Conventional cast steel

5.1.2

5.1.3

5.2.1 Stainless cast steel

5.2.2

6.1.1 Cast iron with lamellar graphite

6.1.2

6.1.3

6.1.4

6.2.1 Spheroidal cast iron

6.2.2

6.2.3

6.3.1 GTW (white malleable cast iron)

6.3.2

6.4.1 GTS (black malleable cast iron)

6.4.2

7.1.1 Aluminium

7.1.2

7.1.3

7.1.4

7.1.5

7.1.6

7.2.1 Magnesium

7.2.2

7.3.1 Copper

7.3.2

Solid carbide tools / Drilling 7.3.5 CuZn (brass)

7.3.3

7.3.4

7.3.6

7.4.1

7.4.2

7.5.1

CuSn (bronze)

7.5.2

7.6.1

CuAlFe (Ampco)

7.6.2

7.8.1

Titanium

7.8.2

7.8.3