Page 431 - Ceratizit Catalog

P. 431

MaxiMill HEC system

B104

Assembly procedures

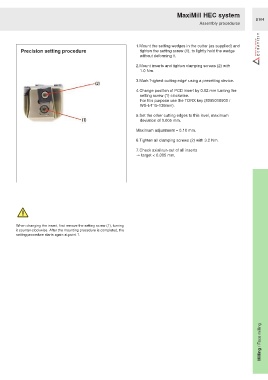

1.Mount the setting wedges in the cutter (as supplied) and

Precision setting procedure tighten the setting screw (1), to lightly hold the wedge

without deforming it.

2.Mount inserts and tighten clamping screws (2) with

1.0 Nm.

3.Mark 'highest cutting edge' using a presetting device.

4.Change position of PCD insert by 0.02 mm turning the

setting screw (1) clockwise.

For this purpose use the TORX key (8095018900 /

WS-L-T15-136mm).

5.Set the other cutting edges to this level, maximum

deviation of 0.005 mm.

Maximum adjustment = 0.10 mm.

6.Tighten all clamping screws (2) with 3.2 Nm.

7.Check axial run-out of all inserts

→ target < 0.005 mm.

When changing the insert, first remove the setting screw (1), turning

it counter-clockwise. After the mounting procedure is completed, the

setting procedure starts again at point 1.

Milling / Face milling