Page 46 - Ceratizit Catalog

P. 46

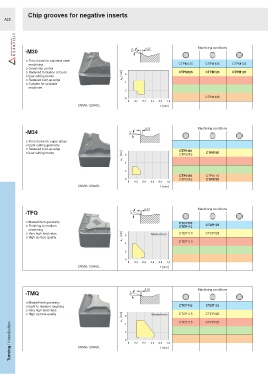

Chip grooves for negative inserts

A25

-M30 15° 0,25 Machining conditions

○ First choice for stainless steel

machining CTPM125 CTPM125 CTPM125

○ Good chip control

○ Reduced formation of burrs [mm] CTPM125 CTPM125 CTPM125

○ Low cutting forces 6

○ Reduced built-up edge a p

4

○ Suitable for unstable

machines

2

CTPM125

0

0 0,2 0,4 0,6 0,8 1,0

CNMG 120408.. f [mm]

0,25 Machining conditions

-M34 15°

○ First choice for super alloys

○ Light cutting geometry

○ Reduced built-up edge CTP5110

[mm] 6 CTP5115

○ Low cutting forces CTP5115

a p

4

2

CTP5110 CTP5110

0 CTP5115 CTP5115

0 0,2 0,4 0,6 0,8 1,0

CNMG 120408.. f [mm]

0,15 Machining conditions

-TFQ 17°

○ Masterfinish geometry CTCP115

○ Finishing to medium CTEP110 CTCP125

machining

○ Very high feed rates [mm] 6 CTEP110 CTCP125

○ High surface quality

a p CTEP110

4

2

0

0 0,2 0,4 0,6 0,8 1,0

CNMG 120408.. f [mm]

0,28 Machining conditions

-TMQ 20°

○ Masterfinish geometry

○ Light to medium roughing CTCP115 CTCP125

○ Very high feed rates

[mm] a p 6 4 CTCP115 CTCP125

○ High surface quality CTCP115 CTCP125

Turning / Introduction CNMG 120408.. 2 0 0 0,2 0,4 0,6 0,8 f [mm]

1,0