Page 48 - Ceratizit Catalog

P. 48

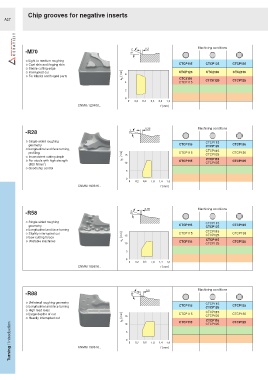

Chip grooves for negative inserts

A27

15,7° 0,3 Machining conditions

-M70

○ Light to medium roughing

○ Cast skin and forging skin CTCP115 CTCP125 CTCP135

○ Stable cutting edge

○ Interrupted cut [mm] 6 CTCP125 CTC2135 CTC2135

○ For blanks and forged parts

a p CTC3110 CTCK120 CTCP125

4 CTCP115

2

0

0 0,2 0,4 0,6 0,8 1,0

CNMG 120408.. f [mm]

0,35 Machining conditions

-R28 20°

○ Single-sided roughing CTCP115

geometry CTCP115 CTCP125 CTCP135

○ Longitudinal and face turning, CTCP115

profiling [mm] CTCP115 CTCP125 CTCP135

○ Inconsistent cutting depth 15

○ For steels with high strength a p CTCP115 CTCP115 CTCP125

² 10 CTCP125

(800 N/mm )

○ Good chip control

5

0

0 0,2 0,6 1,0 1,4 1,8

CNMM 190616.. f [mm]

0,35 Machining conditions

-R58 20°

○ Single-sided roughing CTCP115

geometry CTCP115 CTCP125 CTCP135

○ Longitudinal and face turning CTCP115

○ Slightly interrupted cut [mm] CTCP115 CTCP125 CTCP135

○ Low cutting forces 15

○ Unstable machines a p CTCP115 CTCP115 CTCP125

10 CTCP125

5

0

0 0,2 0,6 1,0 1,4 1,8

CNMM 190616.. f [mm]

0,5 Machining conditions

-R88 20°

○ Unilateral roughing geometry CTCP115

○ Longitudinal and face turning CTCP115 CTCP125 CTCP135

○ High feed rates CTCP115

○ Large depths of cut [mm] CTCP115 CTCP125 CTCP135

○ Heavily interrupted cut a p 15 CTCP115 CTCP115 CTCP125

Turning / Introduction CNMM 190616.. 5 0 0 0,2 0,6 1,0 1,4 f [mm]

CTCP125

10

1,8