Page 51 - Ceratizit Catalog

P. 51

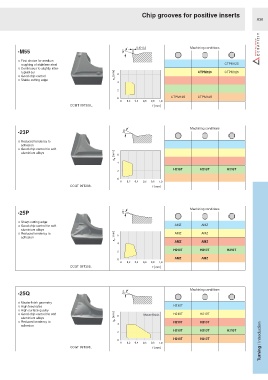

Chip grooves for positive inserts

A30

Machining conditions

-M55 16°

○ First choice for medium

roughing of stainless steel CTPM125

○ Continuous to slightly inter-

rupted cut [mm] CTPM125 CTPM125

○ Good chip control 6

○ Stable cutting edge a p

4

2

CTPM125 CTPM125

0

0 0,2 0,4 0,6 0,8 1,0

CCMT 09T308.. f [mm]

-23P 30° Machining conditions

○ Reduced tendency to

adhesion

○ Good chip control for soft

[mm] 6

aluminium alloys

a p

4

H216T H216T H216T

2

0

0 0,2 0,4 0,6 0,8 1,0

CCGT 09T308.. f [mm]

Machining conditions

-25P 20°

○ Sharp cutting edge

○ Good chip control for soft AMZ AMZ

aluminium alloys

○ Reduced tendency to [mm] 6 AMZ AMZ

adhesion

a p AMZ AMZ

4

H210T H210T H210T

2

AMZ AMZ

0

0 0,2 0,4 0,6 0,8 1,0

CCGT 09T308.. f [mm]

Machining conditions

-25Q 20°

○ Masterfinish geometry

○ High feed rates H210T

○ High surface quality

○ Good chip control for soft [mm] H210T H210T

aluminium alloys 6

○ Reduced tendency to a p H210T H210T

Turning / Introduction

4

adhesion

H210T H210T H210T

2

H210T H210T

0

0 0,2 0,4 0,6 0,8 1,0

CCGT 09T308.. f [mm]