Page 55 - Ceratizit Catalog

P. 55

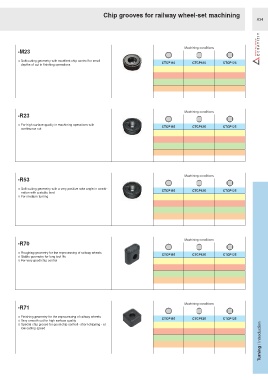

Chip grooves for railway wheel-set machining

A34

Machining conditions

-M23

○ Soft cutting geometry with excellent chip control for small

CTCP115 CTCP125 CTCP125

depths of cut in finishing operations

Machining conditions

-R23

○ For high surface quality in machining operations with

continuous cut CTCP115 CTCP125 CTCP125

Machining conditions

-R53

○ Soft cutting geometry with a very positive rake angle in combi-

CTCP115 CTCP125 CTCP125

nation with a stable land

○ For medium turning

Machining conditions

-R70

○ Roughing geometry for the reprocessing of railway wheels

CTCP115 CTCP125 CTCP125

○ Stable geometry for long tool life

○ For very good chip control

Machining conditions

-R71

○ Finishing geometry for the reprocessing of railway wheels

CTCP115 CTCP125 CTCP125

○ Very smooth cut for high surface quality

Turning / Introduction

○ Special chip groove for good chip control - short-chipping - at

low cutting speed