Page 502 - Ceratizit Catalog

P. 502

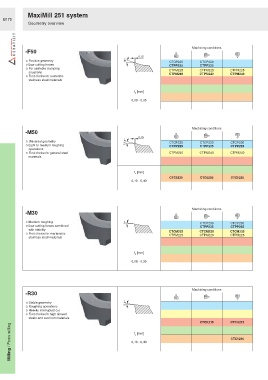

MaxiMill 251 system

B175

Geometry overview

Machining conditions

-F50

0,15

○ Positive geometry 18° CTCP230 CTCP230

○ Low cutting forces

CTPP235 CTPP235

○ For unstable clamping CTPM225 CTPM225 CTPM225

situations

CTPM240 CTPM240 CTPM240

○ First choice for austenitic

stainless steel materials

f z [mm]

0,08 - 0,35

Machining conditions

-M50

0,15

○ Universal geometry 13,5° CTCP230 CTCP230 CTCP230

○ Light to medium roughing CTPP235 CTPP235 CTPP235

operations

○ First choice for general steel CTPM240 CTPM240 CTPM240

materials

f z [mm]

CTC5235 CTC5235 CTC5235

0,10 - 0,40

Machining conditions

-M30

○ Medium roughing 9° CTCP230 CTCP230

○ Low cutting forces combined CTPP235 CTPP235

with stability

○ First choice for martensitic CTCM235 CTCM235 CTCM235

CTPM225

CTPM225

CTPM225

stainless steel materials

f z [mm]

0,08 - 0,35

Machining conditions

-R30

○ Stable geometry 6,5°

○ Roughing operations

○ Heavily interrupted cut

○ First choice for high alloyed

steels and cast iron materials

CTCK215 CTCK215

Milling / Form milling 0,10 - 0,40 CTC5235

f z [mm]