Page 563 - Ceratizit Catalog

P. 563

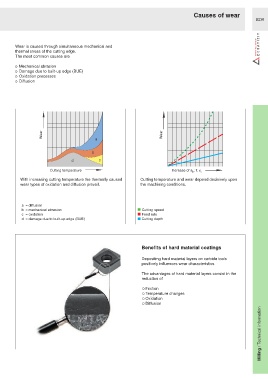

Causes of wear

B236

Wear is caused through simultaneous mechanical and

thermal stress of the cutting edge.

The most common causes are

o Mechanical abrasion

o Damage due to built-up edge (BUE)

o Oxidation processes

o Diffusion

Wear a Wear

b

d c

Cutting temperature Increase of a ; f; v c

p

With increasing cutting temperature the thermally caused Cutting temperature and wear depend decisively upon

wear types of oxidation and diffusion prevail. the machining conditions.

a = diffusion

b = mechanical abrasion Cutting speed

c = oxidation Feed rate

d = damage due to built-up edge (BUE) Cutting depth

Benefits of hard material coatings

Depositing hard material layers on carbide tools

positively influences wear characteristics.

The advantages of hard material layers consist in the

reduction of

○ Friction

○ Temperature changes

○ Oxidation

○ Diffusion

Milling / Technical information