Page 920 - Ceratizit Catalog

P. 920

Application - rotating tools

D45

Insert drills with helical chip flutes

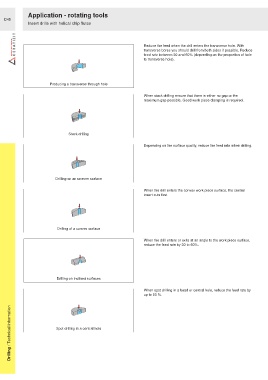

Reduce the feed when the drill enters the transverse hole. With

transverse bores you should drill from both sides if possible. Reduce

feed rate between 30 and 60% (depending on the proportion of hole

to transverse hole).

Producing a transverse through hole

When stack drilling ensure that there is either no gap or the

maximum gap possible. Good work piece clamping is required.

Stack drilling

Depending on the surface quality, reduce the feed rate when drilling.

Drilling on an uneven surface

When the drill enters the convex work piece surface, the central

insert cuts first.

Drilling of a convex surface

When the drill enters or exits at an angle to the work piece surface,

reduce the feed rate by 30 to 60%.

Drilling on inclined surfaces

When spot drilling in a bead or central hole, reduce the feed rate by

up to 50 %.

Drilling / Technical information Spot drilling in a central hole