Page 204 - Parlec Catalog

P. 204

Technical Information

202 Compression Stroke Adjustment

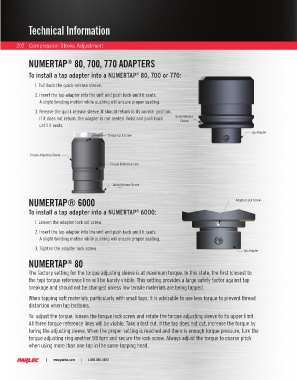

NUMERTAP 80, 700, 770 ADAPTERS

®

To install a tap adapter into a NUMERTAP 80, 700 or 770:

®

1. Pull back the quick-release sleeve.

2. Insert the tap adapter into the unit and push back until it seats.

A slight twisting motion while pushing will ensure proper seating.

3. Release the quick release sleeve. It should return to its normal position.

If it does not return, the adapter is not seated. Twist and push back Quick Release

Sleeve

until it seats.

Tap Adapter

Torque Lock Screw

Torque Adjusting Sleeve

Torque Reference Line

Quick Release Sleeve

NUMERTAP® 6000 Adapter Lock Screw

To install a tap adapter into a NUMERTAP 6000:

®

1. Loosen the adapter lock set screw.

2. Insert the tap adapter into the unit and push back until it seats.

A slight twisting motion while pushing will ensure proper seating.

3. Tighten the adapter lock screw.

Tap Adapter

NUMERTAP 80

®

The factory setting for the torque adjusting sleeve is at maximum torque. In this state, the first (closest to

the tap) torque reference line will be barely visible. This setting provides a large safety factor against tap

breakage and should not be changed unless low tensile materials are being tapped.

When tapping soft materials, particularly with small taps, it is advisable to use less torque to prevent thread

distortion when tap bottoms.

To adjust the torque, loosen the torque lock screw and rotate the torque adjusting sleeve to its upper limit.

All three torque reference lines will be visible. Take a test cut. If the tap does not cut, increase the torque by

turing the adjusting sleeve. When the proper setting is reached and there is enough torque pressure, turn the

torque adjusting ring another 1/8 turn and secure the lock screw. Always adjust the torque to coarse pitch

when using more than one tap in the same tapping head.

| www.parlec.com | 1-800-866-5872