Page 223 - Parlec Catalog

P. 223

Technical Information

Roughing Speeds, Feed Rates & Machining Allowance 221

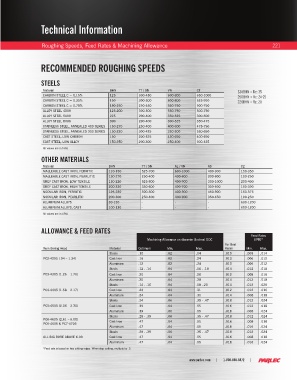

RECOMMENDED ROUGHING SPEEDS

STEELS

Material BHN TT / SN VN CT 330BHN = Rc: 35

CARBON STEEL C = 0.15% 125 300-450 600-800 650-1000 250BHN = Rc: 24-25

CARBON STEEL C = 0.35% 150 300-500 600-800 625-950 220BHN = Rc: 20

CARBON STEEL C = 0.70% 180-250 250-450 550-750 500-750

ALLOY STEEL 4000 125-200 300-500 550-750 500-750

ALLOY STEEL 5000 225 200-400 350-525 300-600

ALLOY STEEL 8000 300 200-400 300-525 350-475

STAINLESS STEEL, ANNEALED 400 SERIES 150-270 250-400 400-600 475-750

STAINLESS STEEL, ANNEALED 300 SERIES 150-220 300-425 350-500 550-650

CAST STEEL, LOW CARBON 150 200-325 450-650 400-550

CAST STEEL, LOW ALLOY 150-250 200-300 250-400 300-425

All values are in SFM.

OTHER MATERIALS

Material BHN TT / SN AL / VN AS C2

MALLEABLE CAST IRON, FERRITIC 110-150 525-700 600-1000 400-900 150-350

MALLEABLE CAST IRON, PEARLITIC 150-270 250-400 400-800 300-800 100-250

GREY CAST IRON, LOW TENSILE 150-220 525-800 400-900 300-1000 200-400

GREY CAST IRON, HIGH TENSILE 200-330 350-600 400-700 300-600 150-300

NODULAR IRON, FERRITIC 125-230 300-500 400-900 450-900 150-375

NODULAR IRON, PEARLITIC 200-300 250-400 400-900 350-650 100-250

ALUMINUM ALLOYS 30-120 - - - 600-1200

ALUMINUM ALLOYS, CAST 100-130 - - - 600-1200

All values are in SFM.

ALLOWANCE & FEED RATES

Feed Rates

Machining Allowance on diameter (Inches) DOC (IPR)*

For Best

Twin Boring Head Material Optimum Min. Max. Finish Min. Max.

Steels .10 .02 .14 .010 .008 .014

PC2-4205 (.94 – 1.34) Cast Iron .16 .02 .24 .010 .006 .012

Aluminum .12 .02 .24 .010 .006 .012

Steels .12 - .14 .04 .16 - .18 .014 .012 .018

PC3-4305 (1.26 – 1.70) Cast Iron .20 .04 .28 .012 .008 .016

Aluminum .20 .04 .28 .014 .012 .018

Steels .14 - .16 .04 .18 -.20 .014 .012 .020

PC4-4405 (1.58 – 2.17) Cast Iron .24 .04 .31 .012 .012 .016

Aluminum .24 .04 .31 .014 .008 .018

Steels .24 .06 .35 - .47 .018 .012 .024

PC5-4505 (2.06 – 3.30) Cast Iron .39 .04 .55 .016 .012 .018

Aluminum .39 .06 .55 .018 .008 .024

Steels .28 - .39 .06 .35 - .47 .018 .012 .024

PC6-4605 (2.61 – 6.00) Cast Iron .47 .04 .55 .016 .008 .018

PC6-4606 & PC7-4705

Aluminum .47 .04 .55 .018 .016 .024

Steels .28 - .39 .06 .35 - .47 .018 .012 .024

ALL BIG BORE ABOVE 6.00 Cast Iron .47 .04 .55 .016 .008 .018

Aluminum .47 .04 .55 .018 .016 .024

*Feed rate is based on two cutting edges. When step cutting, multiply by .5.

www.parlec.com | 1-800-866-5872 |