Page 1046 - Tungaloy Catalog

P. 1046

Technical Reference

Drilling Tools

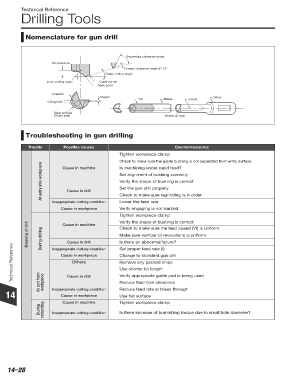

Nomenclature for gun drill

Secondary clearance angle

Oil clearance

Primary clearance angle 8˚~15˚

Outer cutting angle

Inner cutting angle Outer corner

Apex point

Chamfer

Margin Tip Shank V-flute Driver

Oiling hole

Wear surface

(Guide pad) Shank oil hole

Troubleshooting in gun drilling

Trouble Possible causes Countermeasures

Tighten workpiece clamp

Check to make sure the guide bushing is not seperated from entry surface

At entry into workpiece Cause in drill Set alignment of bushing correctly

Is machining under rapid feed?

Cause in machine

Verify the shape of bushing is correct

Set the gun drill properly

Lower the feed rate

Inappropriate cutting condition Check to make sure regrinding is in order

Cause in workpiece Verify engaging is not slanted

Tighten workpiece clamp

Verify the shape of bushing is correct

Breaking of drill During drilling Cause in drill Check to make sure the feed speed (Vf) is uniform

Cause in machine

Make sure number of revolutions is uniform

Is there an abnormal failure?

Technical Reference Inappropriate cutting condition Change to standerd gun drill

Set proper feed rate (f)

Cause in workpiece

Others

Remove any packed chips

Use shorter tip length

Verify appropriate guide pad is being used

Cause in drill

Reduce feed rate at break through

14 At exit from workpiece Inappropriate cutting condition Reduce fluid hole clearance

Use flat surface

Cause in workpiece

Cause in machine

During retracting Inappropriate cutting condition Tighten workpiece clamp

Is there increase of burnishing torque due to small hole diameter?

14–28