Page 29 - Tungaloy Catalog

P. 29

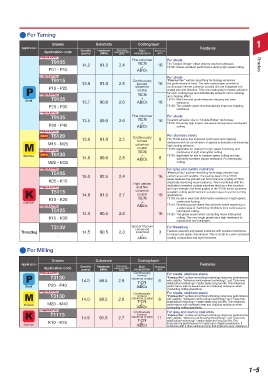

For Turning

Grades Substrate Coating layer 1

Application Transverse Features

Main

Application code Specific Hardness rupture strength composition Thickness

gravity

(µm)

(HRA)

(GPa)

TUNGAL O Y Fine columnar For steels

T9105 TiCN

14.2 91.5 2.4 + 16 The “Double-Bridge” effect delivers excellent adhesion. Grades

P01 - P10 AR2O3 T9105: Shows excellent performance during high speed cutting.

T9115 Continuously “PremiumTec” surface smoothing technology enhances

TUNGAL O Y For steels

13.9 91.0 2.5 formed 16 the performance of tools. The new coating layer consists of

P10 - P20 columnar continuously formed columnar crystals that are integrated into

crystal size and direction. This new coating layer creates adhesion

crystal

TiCN for each coating layer and dramatically prevents micro cracking

TUNGAL O Y and chipping effect.

+

Steel T9125 13.7 90.0 2.6 AR2O3 16 T9115: Well-balanced grade enhances chipping and wear

resistance.

P20 - P30 T9125: The versatile grade that dramatically improves chipping

resistance.

TUNGAL O Y

T9135 Fine columnar For steels

13.5 89.0 2.6 TiCN 16 Excellent adhesion due to “Double-Bridge” technology.

+

P30 - P40 AR2O3 T9135: Extremely high impact resistance during heavy interrupted

cutting.

TUNGAL O Y

T6120 For stainless steels

13.9 91.0 2.5 Continuously 8 The T6100 series has improved notch wear and chipping

formed

M15 - M25 columnar resistance with its combination of special substrates and extremely

high coating adhesion.

crystal T6120: Applicable for medium to high speed machining and

TUNGAL O Y TiCN continuous to light interrupted cutting.

Stainless T6130 + T6130: Applicable for low to medium speed cutting and has

14.6 89.0 2.6 AR2O3 8 extremely excellent impact resistance. For interrupted

M25 - M35 cutting.

For grey and ductile cast irons

TUNGAL O Y

T5105 “PremiumTec” surface smoothing technology delivers high

15.0 92.5 2.4 16 performance with stability. The coating layer of the T5100

K05 - K15 series features fine grained and hard columnar crystals of TiCN

High carbon drastically improving wear resistance. When combined with the

dedicated cemented carbide substrate that has a fine structure

and fine

TUNGAL O Y and high-strength, the three grades of the T5100 series promotes

T5115 columnar excellent cutting performance in a wide range of cast iron turning

14.8 91.5 2.7 crystal 16 applications.

K10 - K20 TiCN T5105: Excels in wear and deformation resistance in high-speed,

Cast lron + continuous turning.

AR2O3 T5115: General purpose grade that achieves stable machining in

TUNGAL O Y a wide range of machining conditions from continuous to

T5125 interrupted cutting.

14.0 90.5 2.8 16 T5125: This grade excels when conducting heavy interrupted

K15 - K30 cutting. This very tough grade has a high resistance to

unpredicted tool breakages.

T313V Special Titanium For threading

compound

Threading 14.5 90.5 2.3 (columnar) 3 Features specially engineered substrate with excellent resistance

to impact and plastic deformation. This is credit to a well controlled

+

- AR2O3 coating composition and layer thickness.

For Milling

Grades Substrate Coating layer

Application Features

Transverse

Main

Application code Specific Hardness rupture strength composition Thickness

(HRA)

gravity

(µm)

(GPa)

Continuously

T3130 columnar crystal “PremiumTec” surface smoothing technology improves performance

TUNGAL O Y formed For steels, stainless steels

14.0 89.5 2.8 TiCN 6 with stability. “Adhesion reinforcement technology” and “Columnar

P20 - P40 + stabilization technology” create stable long tool life. This enhances

Steel AR2O3 performance with increased wear and chipping resistance when

conducting milling operations.

TUNGAL O Y Continuously For steels, stainless steels

T3130 formed “PremiumTec” surface smoothing technology improves performance

14.0 89.5 2.8 columnar crystal 6 with stability. “Adhesion reinforcement technology” and “Columnar

+

M20 - M40 TiCN stabilization technology” create stable long tool life. This enhances

Stainless performance with increased wear and chipping resistance when

AR2O3 conducting milling operations.

TUNGAL O Y Continuously For grey and ductile cast irons

T1115 formed “PremiumTec” surface smoothing technology improves performance

14.9 91.5 2.7 columnar crystal 11 with stability. “Adhesion reinforcement technology” and “Columnar

K10 - K25 TiCN stabilization technology” create stable and long tool life. This

+

Cast lron AR2O3 improves the performance for impact and chipping resistance. It

combines with a thick aluminum layer that improves wear resistance.

1–5