Page 33 - Tungaloy Catalog

P. 33

1

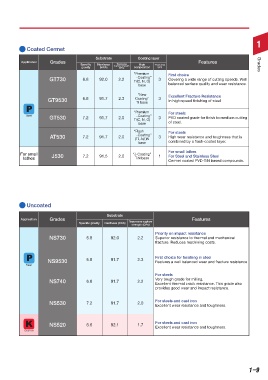

Coated Cermet

Substrate Coating layer

Application Grades Features

Specific Hardness rupture strength Main Thickness Grades

Transverse

gravity (HRA) (GPa) composition (µm)

“Premium First choice

-Coating”

GT730 6.8 92.0 2.2 Ti(C, N, O) 3 Covering a wide range of cutting speeds. Well

base balanced surface quality and wear resistance.

"New Excellent Fracture Resistance

GT9530 6.8 91.7 2.3 Coating" 3 In high-speed finishing of steel

Ti base

“Premium For steels

Steel -Coating”

GT530 7.2 91.7 2.0 Ti(C, N, O) 3 PVD coated grade for finish to medium cutting

base of steel.

“Flash For steels

-Coating”

AT530 7.2 91.7 2.0 (Ti, A R)N 3 High wear resistance and toughness that is

base combined by a flash-coated layer.

For small J530 7.2 91.5 2.0 “J-Coating” 1 For small lathes

lathes TiN base For Steel and Stainless Steel

Cermet coated PVD-TiN based compounds.

Uncoated

Substrate

Application Grades Features

Specific gravity Hardness (HRA) Transverse rupture

strength (GPa)

Priority on impact resistance

NS730 6.8 92.0 2.2 Superior resistance to thermal and mechanical

fracture. Reduces machining costs.

NS9530 6.8 91.7 2.3 First choice for finishing in steel

Features a well balanced wear and fracture resistance

Steel

For steels

NS740 6.8 91.7 2.2 Very tough grade for milling.

Excellent thermal crack resistance. This grade also

provides good wear and impact resistance.

NS530 7.2 91.7 2.0 For steels and cast iron

Excellent wear resistance and toughness.

NS520 6.6 92.1 1.7 For steels and cast iron

Excellent wear resistance and toughness.

Cast lron

1–9