Page 37 - Tungaloy Catalog

P. 37

Ceramics

Ceramics

1

Hard

Cast lron Materials Super Alloy Grades

Increasing wear resistance (hardness) Increasing impact resistance (toughness) FX105 CX710 LX21 LX11

Tungaloy ceramics consist of high purity fine powder Oxides,

Nitrides and Carbides. The fine and dense compacting ensures

superior wear resistance, adhesion resistance, oxidation

resistance and heat resistance.

These grades enable high speed finish to light machining, offering

high accuracy and high quality surface finishes. Ceramic grades

are classified into alumina base and silicon nitride based groups.

These can be selected according to the application.

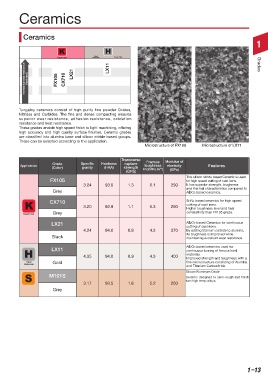

Microstructure of FX105 Microstructure of LX11

Transverse Modulus of

Grade Specific Hardness rupture Fracture

Application toughness elasticity Features

(Color) gravity (HRA) strength K1c(MPa m )

.

1/2

(GPa) (GPa)

This silicon nitride based Ceramic is used

FX105 for high speed cutting of cast irons.

3.24 93.0 1.3 6.1 290 It has superior strength, toughness

Grey and thermal characteristics compared to

AR 2O3 based ceramics.

CX710 Si3N4 based ceramics for high speed

3.20 92.9 1.1 6.3 290 cutting of cast irons.

Higher toughness level and heat

Cast lron Grey conductivity than FX105 grade.

LX21 AR 2O3 based Ceramics for continuous

cutting of cast irons.

4.24 94.0 0.8 4.3 370 By adding titanium carbide to alumina,

its toughness is improved while

Black maintaining excellent wear resistance.

LX11 AR 2O3 based ceramics used for

continuous turning of ferrous hard

4.35 94.0 0.9 4.3 400 materials.

Improved strength and toughness with a

Hard Gold fine microstructure consisting of Alumina

Materials

and Titanium Carbonitride.

Silicon/Aluminum Oxide

M101S Ceramic designed to semi-rough and finish

turn high temp alloys.

3.17 93.5 1.8 5.2 260

Grey

1–13