Page 36 - Tungaloy Catalog

P. 36

PCD (T-DIA)

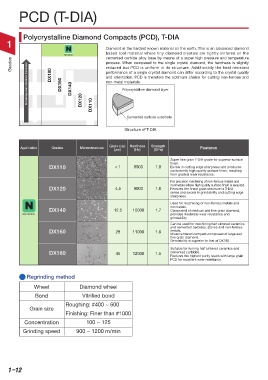

Polycrystalline Diamond Compacts (PCD), T-DIA

1

Diamond is the hardest known material on the earth. This is an advanced diamond

based tool material where tiny diamond crystals are tightly sintered on the

Non-ferrous cemented carbide alloy base by means of a super high pressure and temperature

Grades process. When compared to the single crystal diamond, the hardness is slightly

Increasing wear resistance (hardness) Increasing impact resistance (toughness) DX180 DX160 DX140 DX120 DX110 and orientation. PCD is therefore the optimum choice for cutting non-ferrous and

reduced but PCD is uniform in its structure. Additionally the heat resistant

performance of a single crystal diamond can differ according to the crystal quality

non-metal materials.

Polycrystalline diamond layer

Cemented carbide substrate

Structure of T-DIA

Grain size Hardness Strength

Application Grades Microstructure (µm) (Hv) (GPa) Features

Super fine grain T-DIA grade for superior surface

finish.

DX110 < 1 8500 1.8 Excels in cutting edge sharpness and produces

consistently high quality surface finish, resulting

from gradual wear resistance.

For precision machining of non-ferrous metals and

nonmetals where high quality surface finish is required.

DX120 4.5 9000 1.8 Features the finest grain structure in T-DIA

series and excels in grindability and cutting edge

sharpness.

Used for machining of non-ferrous metals and

nonmetals.

DX140 12.5 10000 1.7 Composed of medium and fine grain diamond,

Non-ferrous provides moderate wear resistance and

grindability.

Can be used for machining half sintered ceramics

and cemented carbides, stones and non-ferrous

DX160 28 11000 1.6 metals.

Mixed sintered compact composed of large and

fine grain diamond.

Grindability is superior to that of DX180.

Suitable for turning half sintered ceramics and

DX180 45 12000 1.5 cemented carbides.

Features the highest purity levels with large grain

PCD for excellent wear resistance.

Regrinding method

Wheel Diamond wheel

Bond Vitrified bond

Roughing: #400 ~ 600

Grain size

Finishing: Finer than #1000

Concentration 100 ~ 125

Grinding speed 900 ~ 1200 m/min

1–12