Page 39 - Tungaloy Catalog

P. 39

Ultra fine Grain Cemented Carbides

Micro-Alloy

1

General

cemented Micro-Alloy grain

carbide cemented carbide

Hardness Grades

Transverse rupture strength

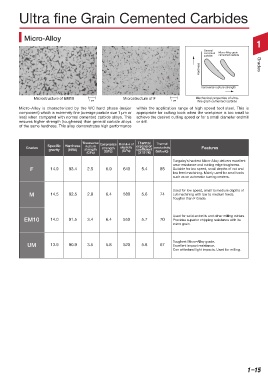

Microstructure of EM10 Microstructure of F Mechanical properties of ultra-

1 µm 1 µm fine grain cemented carbide

Micro-Alloy is characterized by the WC hard phase (major within the application range of high speed tool steel. This is

component) which is extremely fine (average particle size 1 μm or appropriate for cutting tools when the workpiece is too small to

less) when compared with normal cemented carbide alloys. This achieve the desired cutting speed or for a small diameter endmill

ensures higher strength (toughness) than general carbide alloys or drill.

of the same hardness. This alloy demonstrates high performance

Transverse Modulus of Thermal Thermal

Specific Hardness rupture Compression expansion

Grades strength elasticity conductivity Features

gravity (HRA) strength (GPa) coefficient (W//(m ·K))

(GPa) (GPa) (X10 /K)

-6

Tungaloy’s hardest Micro-Alloy delivers excellent

wear resistance and cutting edge toughness.

F 14.9 93.4 2.5 6.9 640 5.4 85 Suitable for low speed, small depths of cut and

low feed machining. Mainly used for small tools

such as on automatic turning centers.

Used for low speed, small to medium depths of

M 14.5 92.5 2.8 6.4 580 5.6 74 cut machining with low to medium feeds.

Tougher than F Grade.

Used for solid endmills and other milling cutters.

EM10 14.0 91.5 3.4 6.4 550 5.7 70 Provides superior chipping resistance with its

micro grain.

Toughest Micro-Alloy grade.

UM 13.9 90.9 3.5 5.8 520 5.8 67 Excellent impact resistance.

Can withstand light impacts. Used for milling.

1–15