Page 35 - Tungaloy Catalog

P. 35

Transverse

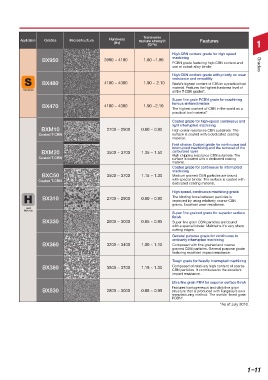

Application Grades Microstructure Hardness rupture strength Features

(Hv) 1

(GPa)

High CBN content grade for high speed

BX950 3900 ~ 4100 1.80 ~1.90 machining

PCBN grade featuring high CBN content and

use of cobalt alloy binder. Grades

High CBN content grade with priority on wear

resistance and versatility

BX480 4100 ~ 4300 1.90 ~ 2.10 World’s highest content of CBN in a practical tool

material. Features the highest hardness level of

Superalloys

all the T-CBN grades*.

Super fine grain PCBN grade for machining

BX470 4100 ~ 4300 1.90 ~2.10 ferrous sintered metals

The highest content of CBN in the world as a

practical tool material*.

Coated grade for high-speed continuous and

light interrupted machining

BXM10 2700 ~ 2900 0.80 ~ 0.90 High crater resistance CBN substrate. The

Coated T-CBN surface is coated with a dedicated coating

material.

First choice: Coated grade for continuous and

interrupted machining and the removal of the

BXM20 3500 ~ 3700 1.35 ~ 1.50 carburized layer

Coated T-CBN High chipping resistance CBN substrate. The

surface is coated with a dedicated coating

material.

Coated grade for continuous to interrupted

machining

BXC50 3500 ~ 3700 1.15 ~ 1.30 Medium grained CBN particles are bound

Coated T-CBN with special binder. The surface is coated with

dedicated coating material.

High speed, continuous machining grade

BX310 2700 ~ 2900 0.80 ~ 0.90 The binding force between particles is

improved by using relatively coarse CBN

grains. Excellent wear resistance.

Hard

Materials

Super fine grained grade for superior surface

finish

BX330 2800 ~ 3000 0.85 ~ 0.95 Super fine grain CBN particles are bound

with a special binder. Maintains it’s very sharp

cutting edges.

General purpose grade for continuous to

ordinarily interrupted machining

BX360 3200 ~ 3400 1.00 ~ 1.10 Composed with fine grained and coarse

grained CBN particles. General purpose grade

featuring excellent impact resistance.

Tough grade for heavily interrupted machining

BX380 3500 ~ 3700 1.15 ~ 1.30 Composed of relatively high content of coarse

CBN particles. It contributes to the excellent

impact resistance.

Ultra fine grain PBN for superior surface finish

Features homogeneous and ultra fine grain

BX530 2800 ~ 3000 0.85 ~ 0.95 structure that is produced with Tungaloy’s own

manufacturing method. The worlds’ finest grain

PCBN*.

*As of July 2010.

1–11