Page 332 - Tungaloy Catalog

P. 332

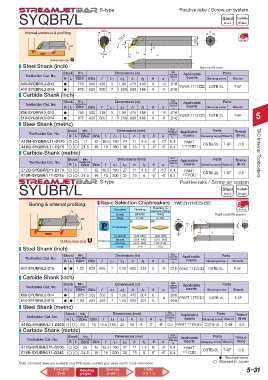

S-type Positive rake / Screw-on system

SYQBR/L Steel Carbide

Shank

Shank

ØDm

Internal undercut & profiling h

122.5˚ ØDs Oil Hole

30˚ f

f2

L2

α L1

Cutting edge style Q

Steel Shank (inch) Right hand (R) shown.

Stock Min Dimensions (in) Std. Applicable Parts

Toolholder Cat. No. bore.dia corner

radius

R L ØDm ØDs f L1 L2 h f2 θ α rε inserts Clamping screw Wrench

A08-SYQBR/L2-D12 d .750 .500 .438 5 1.00 .475 .188 0 -10 .016 YWMT 11T2oo CSTB-2L T-6F

A10-SYQBR/L2-D14 d .875 .625 .500 7 1.250 .600 .188 0 -8 .016

Carbide Shank (inch)

Std.

Stock Min Dimensions (in) corner Applicable Parts

Toolholder Cat. No. bore.dia radius inserts

R L ØDm ØDs f L1 L2 h f2 θ α rε Clamping screw Wrench

E08-SYQBR/L2-D12 d .750 .500 .438 5 1.00 .475 .188 0 -10 .016 YWMT 11T2oo CSTB-2L T-6F 5

E10-SYQBR/L2-D14 d .875 .625 .500 7 1.250 .600 .188 0 -8 .016

Steel Shank (metric)

Std.

Stock Min Dimensions (mm) corner Applicable Parts Torque

Toolholder Cat. No. bore.dia. radius

R L ØDm ØDs f L1 L2 h f2 θ α rε inserts Clamping screw Wrench (N·m)

A12M-SYQBR/L11-D170 17 12 10.5 150 24 11 4.5 -5˚ -10˚ 0.4 YWMT CSTB-2L T-6F 0.6

A16Q-SYQBR/L11-D215 21.5 16 13 180 30 15 5 -5˚ -8˚ 0.4 11T2oo

Carbide Shank (metric) TAC Internal Toolholders

Std.

Stock Min Dimensions (mm) corner Applicable Parts Torque

Toolholder Cat. No. bore.dia. radius

R L ØDm ØDs f L1 L2 h f2 θ α rε inserts Clamping screw Wrench (N·m)

E12Q-SYQBR/L11-D170 17 12 10.5 180 27 11 4.5 -5˚ -10˚ 0.4 YWMT CSTB-2L T-6F 0.6

E16R-SYQBR/L11-D215 21.5 16 13 200 32 15 5 -5˚ -8˚ 0.4 11T2oo

S-type Positive rake / Screw-on system

SYUBR/L Steel Carbide

Shank

Shank

Boring & internal profiling Basic Selection Chipbreakers YWoo11T2oo-oo

Operation Finishing Finishing to Oil Hole

medium cutting

Grade GT9530 T9125 Right hand (R) shown.

60˚ Page 2-139 2-139 ØDm h

ZF ZM L2

93°

Chipbreaker ØDs

Steel f

f2 L1

Vc (SFM) (400-850) (400-800) α

ap (in)

Cutting edge style U Continuous f (in/rev) (.008-.040) (.015-.080)

(.03-.010)

(.001-.006)

Steel Shank (inch) rε (in) .016 .032

Stock Min Dimensions (in) Std. Applicable Parts

Toolholder Cat. No. bore.dia corner

radius

R L ØDm ØDs f L1 L2 h f2 θ α rε inserts Clamping screw Wrench

A10-SYUBR/L2-D16 d d 1.00 .625 .625 7 1.25 .600 .312 0 -8 .016 YWMT 11T2oo CSTB-2L T-6F

Carbide Shank (inch)

Std.

Stock Min Dimensions (in) corner Applicable Parts

Toolholder Cat. No. bore.dia radius

R L ØDm ØDs f L1 L2 h f2 θ α rε inserts Clamping screw Wrench

E08-SYUBR/L2-D14 d .875 .500 .563 5 1.06 .475 .307 0 -8 .016 YWMT 11T2oo CSTB-2L T-6F

E10-SYUBR/L2-D16 d d 1.00 .625 .625 7 1.25 .600 .307 0 .016

Steel Shank (metric)

Std.

Stock Min Dimensions (mm) corner Applicable Parts Torque

Toolholder Cat. No. bore.dia. radius

R L ØDm ØDs f L1 L2 h f2 θ α rε inserts Clamping screw Wrench (N·m)

A16Q-SYUBR/L11-D200 20 16 15.5 180 35 15 8 0˚ -8˚ 0.4 YWMT 11T2oo CSTB-2L T-6F 0.6

Carbide Shank (metric)

Std.

Stock Min Dimensions (mm) corner Applicable Parts Torque

Toolholder Cat. No. bore.dia. radius

R L ØDm ØDs f L1 L2 h f2 θ α rε inserts Clamping screw Wrench (N·m)

E12Q-SYUBR/L11-D200 20 12 13.5 180 27 11 7.5 0˚ -8˚ 0.4 YWMT CSTB-2L T-6F 0.6

E16R-SYUBR/L11-D245 24.5 16 16 200 32 15 8 0˚ -8˚ 0.4 11T2oo

: Stocked items.

: Stocked in Japan

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Features Relating Sleeves Parts 5–31

(5-6) pages (5-64~) (13-1~)