Page 619 - Tungaloy Catalog

P. 619

Screw-on type TAC Mills

T/EAW13 ~ .197in Air Hole Steel Stainless Cast Iron Non-ferrous

45°

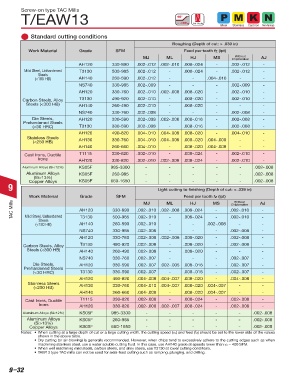

Standard cutting conditions

Roughing (Depth of cut: > .039 in)

Work Material Grade SFM Feed per tooth fz (ipt)

Without

MJ ML HJ MS Chipbreaker AJ

AH120 330-890 .002-.012 .002-.010 .008-.024 - .002-.012 -

Mild Steel, Unhardened T3130 500-985 .002-.012 - .008-.024 - .002-.012 -

Steels

(<180 HB) AH140 260-590 .002-.012 - - .004-.010 - -

NS740 330-985 .002-.009 - - - .002-.009 -

AH120 330-760 .002-.010 .002-.008 .008-.020 - .002-.010 -

Carbon Steels, Alloy T3130 490-920 .002-.010 - .008-.020 - .002-.010 -

Steels (<300 HB) AH140 260-490 .002-.010 - .008-.020 - - -

NS740 330-760 .002-.008 - - - .002-.008 -

Die Steels, AH120 330-590 .002-.008 .002-.006 .008-.016 - .002-.008 -

Prehardened Steels

(<30 HRC) T3130 330-590 .002-.008 - .008-.016 - .002-.008 -

AH120 490-820 .004-.010 .004-.008 .008-.020 - .004-.010 -

Stainless Steels

(<250 HB) AH130 330-760 .004-.010 .004-.008 .008-.020 .004-.008 - -

AH140 260-660 .004-.010 - .008-.020 .004-.008 - -

Cast Irons, Ductile T1115 330-820 .002-.010 - .008-.024 - .002-.010 -

Irons AH120 330-820 .002-.010 .002-.008 .008-.024 - .002-.010 -

Aluminum Alloys (Si<12%) KS05F 985-3300 - - - - - .002-.008

Aluminum Alloys KS05F 260-985 - - - - - .002-.008

(Si>13%)

Copper Alloys KS05F 660-1650 - - - - - .002-.008

9 Light cutting to finishing (Depth of cut: < .039 in)

Work Material Grade SFM MJ ML Feed per tooth fz (ipt) Without AJ

TAC Mills AH120 330-890 .002-.010 .002-.008 .008-.024 - .002-.010 -

MS

HJ

Chipbreaker

Mild Steel, Unhardened

Steels T3130 500-985 .002-.010 - .008-.024 - .002-.010 -

(<180 HB) AH140 260-590 .002-.010 - - .002-.008 - -

NS740 330-985 .002-.008 - - - .002-.008 -

AH120 330-760 .002-.008 .002-.006 .008-.020 - .002-.008 -

Carbon Steels, Alloy T3130 490-920 .002-.008 - .008-.020 - .002-.008 -

Steels (<300 HB) AH140 260-490 .002-.008 - .008-.020 - - -

NS740 330-760 .002-.007 - - - .002-.007 -

Die Steels, AH120 330-590 .002-.007 .002-.005 .008-.016 - .002-.007 -

Prehardened Steels

(<30 HRC) T3130 330-590 .002-.007 - .008-.016 - .002-.007 -

AH120 490-820 .004-.008 .004-.007 .008-.020 - .004-.008 -

Stainless Steels AH130 330-760 .004-.010 .004-.007 .008-.020 .004-.007 - -

(<250 HB)

AH140 260-660 .004-.008 - .008-.020 .004-.007 - -

Cast Irons, Ductile T1115 330-820 .002-.008 - .008-.024 - .002-.008 -

Irons AH120 330-820 .002-.008 .002-.007 .008-.024 - .002-.008 -

Aluminum Alloys (Si<12%) KS05F 985-3300 - - - - - .002-.008

Aluminum Alloys KS05F 260-985 - - - - - .002-.008

(Si>13%)

Copper Alloys KS05F 660-1650 - - - - - .002-.008

Notes: • When cutting at a large depth of cut or a large cutting width, the cutting speed (v c) and feed (fz) should be set to the lower side of the values

shown in the above table.

• Dry cutting (or air-blowing) is generally recommended. However, when chips tend to excessively adhere to the cutting edges such as when

machining stainless steel, use a water soluble cutting fluid. In this case, use AH140 grade at speeds lower than v c = 400 SFM.

• When wet machining mild steels, carbon steels, and alloy steels, use T3130 at lower cutting conditions.

• TAW13 type TAC mills can not be used for axial-feed cutting such as ramping, plunging, and drilling.

9–32