Page 623 - Tungaloy Catalog

P. 623

TAC Mills

TMD4400RIU/RBU

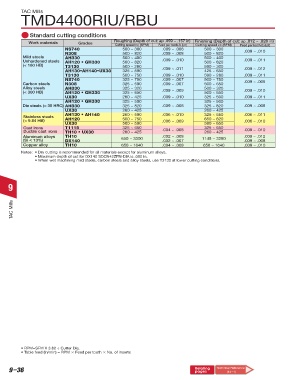

Standard cutting conditions

Work materials Grades Roughing (Depth of cut: ap .059 ~ .157 in) Finishing (Depth of cut: ap .012 ~ .028 in)

Cutting speed vc (SFM)

Feed per tooth fz (ipt)

Cutting speed vc (SFM)

Feed per tooth fz (ipt)

NS740 500 ~ 300 .009 ~ .008 500 ~ 300 .009 ~ .010

N308 500 ~ 820 .009 ~ .008 500 ~ 820

Mild steels AH330 500 ~ 400 500 ~ 400

Unhardened steels AH120 • GH330 500 ~ 820 .009 ~ .010 500 ~ 820 .009 ~ .011

(< 180 HB) T3130 500 ~ 280 590 ~ 300

AH130• AH140• UX30 325 ~ 590 .009 ~ .011 425 ~ 650 .009 ~ .012

T3130 500 ~ 750 .009 ~ .010 590 ~ 280 .009 ~ .011

NS740 325 ~ 750 .009 ~ .007 500 ~ 750

Carbon steels N308 325 ~ 590 .009 ~ .007 500 ~ 650 .009 ~ .009

Alloy steels AH330 325 ~ 320 500 ~ 320

(< 300 HB) AH120 • GH330 325 ~ 650 .009 ~ .009 500 ~ 650 .009 ~ .010

UX30 260 ~ 425 .009 ~ .010 325 ~ 500 .009 ~ .011

AH120 • GH330 325 ~ 500 325 ~ 500

Die steels (< 30 HRC) AH330 325 ~ 820 .009 ~ .006 325 ~ 820 .009 ~ .008

UX30 260 ~ 425 260 ~ 425

Stainless steels AH130 • AH140 260 ~ 590 .006 ~ .010 325 ~ 650 .006 ~ .011

(< 9.84 HB) AH120 500 ~ 750 .006 ~ .009 650 ~ 820 .006 ~ .010

UX30 500 ~ 590 590 ~ 650

Cast irons T1115 325 ~ 650 325 ~ 650

Ductile cast irons TH10 • UX30 260 ~ 425 .004 ~ .008 260 ~ 425 .009 ~ .010

Aluminum alloys TH10 650 ~ 3300 .002 ~ .008 1148 ~ 3280 .009 ~ .012

(Si < 13%) DX140 .002 ~ .007 .009 ~ .008

Copper alloy TH10 650 ~ 1640 .004 ~ .008 650 ~ 1640 .009 ~ .010

Notes: • Dry cutting is recommended for all materials except for aluminum alloys.

• Maximum depth of cut for DX140 SDCN42ZFN-DIA is .080 in.

• When wet machining mild steels, carbon steels and alloy steels, use T3130 at lower cutting conditions.

9

TAC Mills

• RPM=SFM X 3.82 ÷ Cutter Dia.

• Table feed (in/min) = RPM Feed per tooth No. of inserts

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–36 Relating Technical Reference

pages

(14-1)