Page 66 - Tungaloy Catalog

P. 66

Basic Chipbreakers Positive Inserts

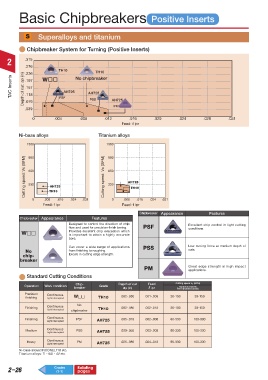

Superalloys and titanium

Chipbr

Chipbreaker System for Turning (Positive Inserts)eaker System for Turning (Positive Inserts)

2 .315

.276

TH10 No chipbreaker

TH10

.236

TAC Inserts Depth of cut: ap (in) .197 W PSF AH725 AH725

.157

.118

.079

PM

.039 PSS AH725

0 .004 .008 .012 .016 .020 .024 .028 .031

Feed: f ipr

Ni-base alloys Titanium alloys

1300 1300

980

980

Cutting speed: Vc (SFM) 650 AH725 Cutting speed: Vc (SFM) 650 AH725

330

330

TH10

0 .008 TH10 .016 .024 .031 0 .008 .016 .024 .031

Feed: f ipr Feed: f ipr

Chipbreaker Appearance Features

Chipbreaker Appearance Features

Designed to control the direction of chip Excellent chip control in light cutting

flow and used for precision-finish boring. PSF conditions.

Wuu Provides excellent chip evacuation which

is important to attain a highly accurate

bore.

Can cover a wide range of applications PSS Low cutting force at medium depth of

No from finishing to roughing. cuts.

chip- Excels in cutting edge strength.

breaker

PM Great edge strength in high impact

applications.

Standard Cutting Conditions

Chip- Depth of cut Feed Cutting speed vc (SFM)

Operation Work condition Grade Hardened steels

breaker ap (in) f ipr Pre-hardened steels

Precision Continuous

finishing Light interrupted Wuu TH10 .002-.080 .001-.008 20-150 30-150

No

Finishing Continuous TH10 .002-.080 .002-.012 20-150 30-150

Light interrupted chipbreaker

Finishing Continuous PSF AH725 .005-.015 .002-.008 80-330 100-330

Light interrupted

Medium Continuous PSS AH725 .020-.060 .003-.008 80-330 100-330

Light interrupted

Heavy Continuous PM AH725 .025-.080 .004-.012 80-330 100-330

Light interrupted

Ni-base alloys: INCONEL718 etc.

Titanium alloys: Ti - 6Al - 4V etc.

2–26 Grades Relating

pages

(1-1)