Page 64 - Tungaloy Catalog

P. 64

Basic Chipbreakers Positive Inserts

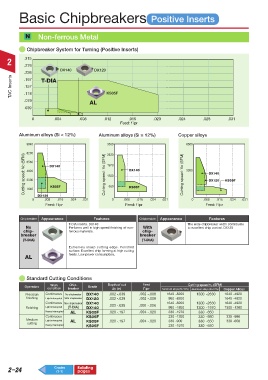

Non-ferrous Metal

Chipbreaker System for Turning (Positive Inserts)

2 .315

.276

DX140 DX120

.236

TAC Inserts .157 T-DIA KS05F

.197

.118

.079 AL

.039

0 .004 .008 .012 .016 .020 .024 .028 .031

Feed: f ipr

Aluminum alloys (Si < 12%) Aluminum alloys (Si ≥ 12%) Copper alloys

9840 3300 6560

8200 2630

Cutting speed: Vc (SFM) 4920 DX140 Cutting speed: Vc (SFM) 1970 DX140 Cutting speed: Vc (SFM) 3300 DX140 KS05F

6560

1300

3300

DX120

1640

DX120 KS05F 650 KS05F

0 .008 .016 .024 .031 0 .008 .016 .024 .031 0 .008 .016 .024 .031

Feed: f ipr Feed: f ipr Feed: f ipr

Chipbreaker Appearance Features Chipbreaker Appearance Features

T-DIA inserts. DX140 The wide chipbreaker width contributes

No Performs well in high speed finishing of non- With to excellent chip control. DX120

chip- ferrous materials. chip-

breaker breaker

(T-DIA) (T-DIA)

Extremely sharp cutting edge. Polished

surface. Excellent chip forming at high cutting

AL feeds. Low power consumption.

Standard Cutting Conditions

Work Chip- Depth of cut Feed Cutting speed vc (SFM)

Operation condition breaker Grade ap (in) f ipr Aluminum alloys( Si<12%) Aluminum alloys (Si>12%) Copper Alloys

Precision Continuous No chipbreaker DX140 .002 -.039 .002 -.006 1640 -8200 1300 -2630 1640 -4920

finishing Light interrupted With chipbreaker DX120 .002 -.039 .002 -.008 980 -8200 1640 -4920

Continuous No chipbreaker DX140 1640 -8200 1300 -2630 1640 -4920

Finishing Light interrupted (T-DIA) DX140 .002 -.039 .002 -.006 980 -1800 1300 -1970 1300 -1200

Heavy interrupted AL KS05F .020 -.197 .004 -.020 330 -1970 330 -650

Continuous KS05F 330 -1200 330 -980 330 -980

Medium Light interrupted AL KS05F .020 -.197 .004 -.020 330 -900 330 -650 330 -650

cutting

Heavy interrupted KS05F 330 -1970 330 -650

2–24 Grades Relating

pages

(1-1)