Page 749 - Tungaloy Catalog

P. 749

TAC Milling Inserts

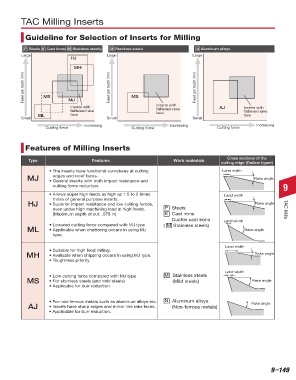

Guideline for Selection of Inserts for Milling

P Steels K Cast irons( M Stainless steels) M Stainless steels N Aluminum alloys

Large Large Large

HJ

MH

Feed per tooth limit MS Feed per tooth limit MS Feed per tooth limit

MJ

Inserts with Inserts with AJ Inserts with

flattened rake flattened rake flattened rake

ML face face face

Small Small Small

Increasing Increasing Increasing

Cutting force Cutting force Cutting force

Features of Milling Inserts

Cross sections of the

Type Features Work materials

cutting edge (Outline figure)

• The inserts have functional curvatures at cutting Land width

edges and relief faces.

MJ • General inserts with both impact resistance and Rake angle

cutting force reduction. 9

• Allows super high feeds as high as 1.5 to 2 times Land width

those of general purpose inserts.

HJ • Superior impact resistance and low cutting forces, Rake angle

even under high machining load at high feeds. P Steels TAC Mills

(Maximum depth of cut: .078 in) K Cast irons

Ductile cast irons Land width

• Lowered cutting force compared with MJ type ( M Stainless steels)

ML • Applicable when chattering occurs in using MJ Rake angle

type.

Land width

• Suitable for high feed milling.

MH • Available when chipping occurs in using MJ type. Rake angle

• Toughness priority.

Land width

• Low cutting force compared with MJ type M Stainless steels

MS • For stainless steels (and mild steels) (Mild steels) Rake angle

• Applicable for burr reduction.

• For non-ferrous metals such as aluminum alloys etc. N Aluminum alloys Rake angle

AJ • Inserts have sharp edges and mirror like rake faces. (Non-ferrous metals)

• Applicable for burr reduction.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–149