Page 745 - Tungaloy Catalog

P. 745

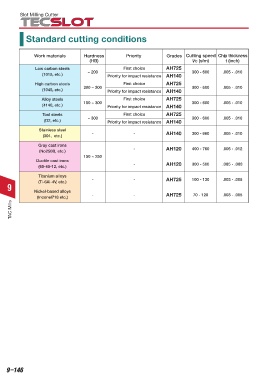

Slot Milling Cutter

Standard cutting conditions

Work materials Hardness Priority Grades Cutting speed Chip thickness

(HB) Vc (sfm) t (inch)

Low carbon steels First choice AH725

(1015, etc.) ~ 200 Priority for impact resistance AH140 300 - 600 .005 - .010

High carbon steels First choice AH725

(1045, etc.) 200 ~ 300 Priority for impact resistance AH140 300 - 600 .005 - .010

Alloy steels First choice AH725

(4140, etc.) 150 ~ 300 Priority for impact resistance AH140 300 - 600 .005 - .010

Tool steels First choice AH725

(D2, etc.) ~ 300 Priority for impact resistance AH140 300 - 600 .005 - .010

Stainless steel

(304, etc.) - - AH140 300 - 660 .005 - .010

Gray cast irons

(No250B, etc.) - AH120 400 - 760 .005 - .012

150 ~ 250

Ductile cast irons

(65-45-12, etc.) - AH120 300 - 500 .005 - .008

Titanium alloys

(Ti-6Al-4V, etc.) - - AH725 100 - 130 .003 - .005

9 Nickel-based alloys

(Inconel718 etc.) - - AH725 70 - 120 .003 - .005

TAC Mills

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–146