Page 816 - Tungaloy Catalog

P. 816

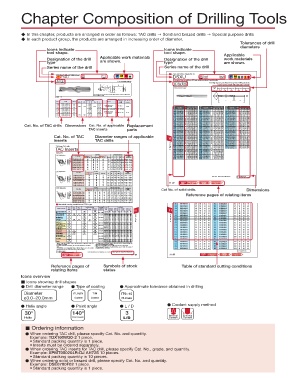

Chapter Composition of Drilling Tools

r In this chapter, products are arranged in order as follows: TAC drills → Solid and brazed drills → Special purpose drills

r In each product group, the products are arranged in increasing order of diameter.

Tolerances of drill

diameters

Icons indicate Icons indicate

tool shape. tool shape. Applicable

Designation of the drill Applicable work materials Designation of the drill work materials

type are shown. type are shown.

Series name of the drill Series name of the drill

Giga Jet Drill for steels (INCH)

IT11~

TDXU Internal IT class DSXU Internal (Ti,A R ) N IT9~10

Coolant

Coated

IT class

Non-ferrous

Coolant

Cast lron

Steel

Stainless

Steel Stainless Non-ferrous Materials Hard Superalloys Cast Iron

0° 2/3/4 5 Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Helix L/D For General Drilling

30° 3/5/8 140° For High Speed and effi cient Deep Hole Drilling of Steels

L Helix Point angle

R R s L/D Coated solid carbide drills with spiral oil holes

Max.

drilling depth Internal coolant supply Drill Dia. øDc≤3.0 3.0<øDc≤6.0 6.0<øDc≤10.0 10.0<øDc≤18.0 18.0<øDc≤20.0

øDc

øDc øD øDs h6 Tolerances −0.014 0 −0.018 0 −0.022 0 −0.027 0 −0.033 0

Please take note that the new TDX type differs from the older TDX type in the

total length (L) of drill. øDc h8 øDs h6

L/D = 2 140°

Dimensions (in) Clamping Screw Torx Wrench R R S

Dia. Drill Stock Insert

ØDs ØD r rs L L

.500 TDXU-0500-02 ● 1.000 3.78

.531 TDXU-0531-02 ● .750 1.25 1.062 2.00 3.87 XPMT040104R- CSTB-2 T-6D Drill Drill Drill

DJ,DS,DW

.562 TDXU-0562-02 ● 1.124 3.96 dia. Cat. No. Stock Dimensions (in) dia. Cat. No. Stock Dimensions (in) dia. Cat. No. Stock Dimensions (in)

R

R s

.625 TDXU-0625-02 ● 1.250 4.15 XPMT050204R-DJ,DS,DW CSTB-2L040 øDc 1/8 DSXU1250F03 øDs .156 .709 1.89 2.80 L øDc 1/8 DSXU1250F05 øDs .156 R 1.10 1.89 R s 3.19 L øDc 1/8 DSXU1250F08 øDs .156 R 1.54 R s 1.89 3.62 L

.687 TDXU-0687-02 ● 1.37 4.62 9/64 DSXU1406F03 .156 .787 1.89 2.87 9/64 DSXU1406F05 .156 1.26 1.89 3.35 9/64 DSXU1406F08 .156 1.73 1.89 3.82

DSXU1562F08

5/32

.750 TDXU-0750-02 ● 1.50 4.81 XPMT06X308R- CSTB-2.2R T-7D 11/64 DSXU1719F03 .156 .787 1.89 2.87 11/64 DSXU1719F05 .156 .188 1.26 1.42 1.89 1.97 3.35 3.58 11/64 DSXU1719F08 .156 .188 1.73 1.97 1.89 1.97 3.82 4.13

5/32

DSXU1562F05

DSXU1562F03

5/32

DJ,DS,DW

.812 TDXU-0812-02 ● 1.00 1.46 1.62 4.99 3/16 DSXU1875F03 .188 .906 1.97 3.07 3/16 DSXU1875F05 .188 1.57 1.97 3.70 3/16 DSXU1875F08 .188 2.17 1.97 4.33

.188 .984 1.97 3.15

.875 TDXU-0875-02 ● 1.75 5.18 XPMT07H308R- 13/64 DSXU2031F03 d .203 1.10 2.05 3.23 13/64 DSXU2031F05 d .203 1.73 2.05 3.78 13/64 DSXU2031F08 .203 2.40 2.05 4.45

.937 TDXU-0937-02 ● 1.87 2.28 5.37 DJ,DS,DW CSTB-2.5 T-8D #A15/64 DSXU2344F03 d .219 1.18 2.05 3.23 #A15/64 DSXU2344F05 d d .219 .234 1.89 1.89 2.05 2.05 3.94 3.94 #A15/64 DSXU2344F08 .219 .234 2.60 2.60 2.05 2.05 4.65 4.65

7/32

DSXU2188F05

7/32

DSXU2188F03

DSXU2188F08

7/32

.234 1.18 2.05 3.23

1.00 TDXU-1000-02 ● 2.00 5.56 #E1/4 DSXU2500F03 d .250 1.30 2.09 3.39 #E1/4 DSXU2500F05 d .250 2.05 2.09 4.13 #E1/4 DSXU2500F08 .250 2.83 2.09 4.92

1.06 TDXU-1062-02 ● 2.12 5.74 17/64 DSXU2656F03 d .266 1.38 2.09 3.46 17/64 DSXU2656F05 d .266 2.20 2.09 4.29 17/64 DSXU2656F08 .266 3.03 2.09 5.12

DSXU2813F05

DSXU2813F08

9/32

9/32

9/32

DSXU2813F03

1.13 TDXU-1125-02 ● 1.25 1.58 2.25 5.93 XPMT08T308R- CSTB-3 T-9D 19/64 DSXU2969F03 d d .281 1.50 2.13 3.62 19/64 DSXU2969F05 d d .281 .297 2.36 2.52 2.13 2.13 4.49 4.65 19/64 DSXU2969F08 .281 .297 3.27 3.46 2.13 2.13 5.39 5.59

.297 1.57 2.13 3.70

DJ,DS,DW

2.37

6.12

Dimensions

Cat. No. of TAC drills TDXU-1187-02 ● ● 2.50 Cat. No. of applicable Replacement 21/64 DSXU3281F03 d .313 1.57 2.13 3.70 21/64 DSXU3281F05 d d .313 .328 .344 2.52 2.68 2.83 2.13 2.17 2.17 4.65 5.00 5.00 21/64 DSXU3281F08 .313 .328 .344 3.46 3.70 3.90 2.13 2.17 2.17 5.59 6.06 6.06

1.19

DSXU3125F05

DSXU3125F03

5/16

5/16

DSXU3125F08

5/16

.328 1.69 2.17 3.94

TDXU-1250-02

6.31

1.25

11/32 DSXU3438F03

.344 1.77 2.17 3.94

11/32 DSXU3438F05

11/32 DSXU3438F08

1.312 TDXU-1312-02 ● 2.62 6.90 23/64 DSXU3594F03 d .359 1.89 2.20 4.17 23/64 DSXU3594F05 d d .359 2.99 2.20 5.35 23/64 DSXU3594F08 .359 4.11 2.20 6.54

7.09

1.38 TDXU-1375-02 ● 2.75 TAC inserts T-15D parts 3/8 DSXU3750F03 d .375 1.97 2.20 4.17 3/8 DSXU3750F05 d .375 3.15 2.20 5.35 3/8 DSXU3750F08 .375 4.33 2.20 6.54

1.44 TDXU-1437-02 ● 1.97 2.87 7.28 XPMT110412R- CSTB-4 25/64 DSXU3906F03 d d .391 1.97 2.20 4.17 25/64 DSXU3906F05 d d .391 .406 3.15 3.31 2.20 2.40 5.35 5.87 25/64 DSXU3906F08 .391 .406 4.33 4.57 2.20 2.40 6.54 7.17

.406 2.09 2.40 4.57

13/32 DSXU4063F03

13/32 DSXU4063F08

13/32 DSXU4063F05

DJ,DS,DW

1.50 TDXU-1500-02 ● 3.00 7.46 27/64 DSXU4219F03 d d .422 2.17 2.40 4.57 27/64 DSXU4219F05 d d .422 .438 3.46 3.62 2.40 2.44 5.87 6.22 27/64 DSXU4219F08 .422 .438 4.76 5.00 2.40 2.44 7.17 7.64

DSXU4375F05

DSXU4375F03

7/16

DSXU4375F08

7/16

.438 2.28 2.44 4.80

7/16

●

TDXU-1562-02

1.56

3.37 Diameter ranges of applicable

11Cat. No. of TAC 3.12 2.69 7.65 11 29/64 DSXU4531F03 d d d d d .453 2.36 2.44 4.80 29/64 DSXU4531F05 d d d d .453 .469 .484 .500 .516 3.78 3.78 4.09 4.09 4.41 2.44 2.44 2.48 2.48 2.52 6.22 6.22 6.57 6.57 6.93 29/64 DSXU4531F08 .453 .469 .484 .500 .516 5.20 5.20 5.63 5.63 6.06 2.44 2.44 2.48 2.48 2.52 7.64 7.64 8.11 8.11 8.58

1.63

7.84

TDXU-1625-02

3.25

.469 2.36 2.44 4.80

●

15/32 DSXU4688F03

15/32 DSXU4688F08

15/32 DSXU4688F05

1.50

31/64 DSXU4844F05

31/64 DSXU4844F08

TDXU-1687-02

●

31/64 DSXU4844F03

.484 2.56 2.48 5.04

8.03

1.69

1/2

1/2

1/2

DSXU5000F03

DSXU5000F08

.500 2.56 2.48 5.04

DSXU5000F05

3.62 TAC drills

Drilling Tools inserts ● ● ● ● 2.17 3.75 8.40 XPMT150512R- CSTB-5 T-20D Drilling Tools 17/32 DSXU5313F03 d d d d d .531 2.76 2.52 5.28 17/32 DSXU5313F05 d d d .531 .547 .563 .578 .594 .609 4.41 4.41 4.72 4.72 5.04 5.04 2.52 2.52 2.56 2.56 2.60 2.60 6.93 6.93 7.28 7.28 7.64 7.64 17/32 DSXU5313F08 .531 .547 .563 .578 .594 .609 6.06 6.06 6.50 6.50 6.93 6.93 2.52 2.52 2.56 2.56 2.60 2.60 8.58 8.58 9.06 9.06 9.53 9.53

1.75

●

3.50

8.21

TDXU-1750-02

33/64 DSXU5156F05

33/64 DSXU5156F03

33/64 DSXU5156F08

.516 2.76 2.52 5.28

1.81

TDXU-1812-02

DJ,DS,DW

35/64 DSXU5469F05

.547 2.76 2.52 5.28

35/64 DSXU5469F08

35/64 DSXU5469F03

1.88

8.59

TDXU-1875-02

DSXU5625F08

9/16

DSXU5625F03

.563 2.95 2.56 5.51

9/16

DSXU5625F05

9/16

8.78

TDXU-1937-02

3.87

1.94

37/64 DSXU5781F05

37/64 DSXU5781F03

37/64 DSXU5781F08

.578 2.95 2.56 5.51

Giga Power Drills

TDX-type TAC drills

.594 3.15 2.60 5.75

2.00

4.00

19/32 DSXU5938F08

8.96

19/32 DSXU5938F03

TDXU-2000-02

19/32 DSXU5938F05

DSE

39/64 DSXU6094F03

.609 3.15 2.60 5.75

39/64 DSXU6094F05

39/64 DSXU6094F08

TAC Inserts

5/8

DSXU6250F03

7.64

2.60

DSXU6250F05

(Ti,A R ) N

5/8

External

7.99

.641 3.35 2.64 5.98

41/64 DSXU6406F03

Coated

2.64 IT class

21/32 DSXU6562F05

.656 3.35 2.64 5.98

21/32 DSXU6562F03

Coolant

7.99

2.64

11/16 DSXU6875F03 d d d .625 3.15 2.60 5.75 41/64 DSXU6406F05 d d .625 .641 .656 .688 5.04 5.35 5.35 5.67 2.60 IT9~10 5/8 DSXU6250F08 Steel Cast Iron .625 Stainless 6.93 Superalloys 9.53 Materials Hard

.688 3.54 2.68 6.22

8.35

11/16 DSXU6875F05

2.68

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Inserts 45/64 DSXU7031F03 .703 3.54 2.68 6.22 45/64 DSXU7031F05 .703 .719 5.67 5.98 2.68 2.72 8.35 8.70 For Steels

23/32 DSXU7187F03 140°30°

2/3

.719 3.74 2.72 6.46

23/32 DSXU7187F05

DJ chipbreaker Cat. No. Grades Dimensions (in) Applicable 47/64 DSXU7344F03 Point angle .734 3.74 2.72 6.46 47/64 DSXU7344F05 .734 .750 5.98 6.30 2.72 2.76 8.70 9.06 Coated solid carbide drills

L/D

Helix

drill

DSXU7500F03

3/4

3/4

.750 3.94 2.76 6.69

DSXU7500F05

NEW AH725 AH740 GH730 NEW T1115 T1015 A B T ød rε diameters 49/64 DSXU7656F03 .766 3.94 2.76 6.69 49/64 DSXU7656F05 .766 6.30 2.76 9.06

11° XPMT040104R-DJ d d d .169 .169 .063 .063 .091 ø.492 ~ ø.571 25/32 DSXU7812F03 .781 3.94 2.76 6.69 25/32 DSXU7812F05 .781 6.30 øDc 2.76 øDc≤3.0 3.0<øDc≤6.0 6.0<øDc≤10.0 10.0<øDc≤16.0

External coolant supply

9.06

Drill Dia.

XPMT050204R-DJ d d d .205 .205 .094 .094 .091 ø.591 ~ ø.669 Tolerances 0 0 0 0

B ød XPMT06X308R-DJ d d d .236 .236 .118 .118 .098 ø.689 ~ ø.846 −0.014 −0.018 −0.022 −0.027

A T XPMT07H308R-DJ d d d .276 .276 .142 .142 .110 ø.866 ~ ø1.02

XPMT08T308R-DJ d d d .335 .335 .156 .156 .134 ø1.06 ~ ø1.26 140° øDc h8 øDs h8

XPMT110412R-DJ d d d .441 .441 .187 .187 .173 ø1.30 ~ ø1.61

XPMT150512R-DJ d d d .591 .591 .219 .219 .217 ø1.65 ~ ø2.13 R R S

DS chipbreaker Grades Dimensions (in) Applicable L

Cat. No. drill

NEW AH725 AH120 GH730 A B T ød rε diameters

11° XPMT040104R-DS d d .169 .169 .063 .063 .091 d : Stocked items.

ø.492 ~ ø.571

Most unmarked items are available on a RFQ basis, contact your sales rep for more information. .205 .205 .094 .094 .091 ø.591 ~ ø.669 L/D = 2 Note: L/D = Hole depth / Drill diameter d : Stocked items.

: Stocked mm dealers.

d

XPMT050204R-DS

d

B ød XPMT06X308R-DS d d .236 .236 .118 .118 .098 ø.689 ~ ø.846 Drill dia. Dimensions (mm) Drill dia. Dimensions (mm)

Note: L/D = Hole depth / Drill diameter

Cat. No.

Stock

11–10 A Relating T Cutting Conditions Technical reference d d d d .276 .276 .142 .142 .110 ø.866 ~ ø1.02 øDc DSE0300F02 Cutting Conditions 3.0 R 16 Regrinding 46 L Technical reference DSE0690F026.9 øDc Cat. No. Stock øDs R 34 40 R s 74 L

R s

XPMT07H308R-DS

øDs

(11-16 )

pages

(15-1)

XPMT08T308R-DS

6.9

.335 .335 .156 .156 .134

ø1.06 ~ ø1.26

Relating

30

pages

(11-85)

XPMT110412R-DS d d .441 .441 .187 .187 .173 ø1.30 ~ ø1.61 11–24 3.0 DSE0310F02 (11-28) 3.1 18 Procedures 49 7.0 (15-1) DSE0700F02 7.0 34 40 74

3.1

31

XPMT150512R-DS d d .591 .591 .219 .219 .217 ø1.65 ~ ø2.13 3.2 DSE0320F02 3.2 18 31 49 7.1 DSE0710F02 7.1 34 40 74

DW chipbreaker Grades Dimensions (in) Applicable 3.3 DSE0330F02 3.3 18 31 49 7.2 DSE0720F02 7.2 34 40 74

3.4

Cat. No. drill Cat No. of solid drills. 20 32 52 7.3 DSE0730F02 7.3 34 40 Dimensions

DSE0340F02

3.4

74

40

NEW AH725 AH740 AH120 GH730 A B T ød rε diameters 3.5 DSE0350F02 3.5 20 32 52 7.4 DSE0740F02 7.4 34 74

11° XPMT040104R-DW d d d .169 .169 .063 .063 .091 ø.492 ~ ø.571 3.6 DSE0360F02 3.6 20 32 52 7.5 DSE0750F02 7.5 34 40 74

XPMT050204R-DW d d d .205 .205 .094 .094 .091 ø.591 ~ ø.669

3.7

DSE0760F02

7.6

32

37

20

52

7.6

79

42

DSE0370F02

B ød XPMT06X308R-DW d d d .236 .236 .118 .118 .098 ø.689 ~ ø.846 3.7 DSE0380F02 Reference pages of relating items

XPMT07H308R-DW d d d .276 .276 .142 .142 .110 ø.866 ~ ø1.02 3.8 3.8 22 33 55 7.7 DSE0770F02 7.7 37 42 79

A T 3.9 DSE0390F02 3.9 22 33 55 7.8 DSE0780F02 7.8 37 42 79

XPMT08T308R-DW d d d .335 .335 .156 .156 .134 ø1.06 ~ ø1.26

XPMT110412R-DW d d d .441 .441 .187 .187 .173 ø1.30 ~ ø1.61 4.0 DSE0400F02 4.0 22 33 55 7.9 DSE0790F02 7.9 37 42 79

XPMT150512R-DW d d d .591 .591 .219 .219 .217 ø1.65 ~ ø2.13 4.1 4.2 DSE0410F02 4.1 22 22 33 33 55 55 8.0 8.1 DSE0800F02 8.0 37 37 42 42 79 79

8.1

DSE0810F02

DSE0420F02

4.2

Standard cutting conditions of TDX-type 4.3 DSE0430F02 4.3 24 34 58 8.2 DSE0820F02 8.2 37 42 79

Troubleshooting Cutting Feed (ipr) 4.4 DSE0440F02 4.4 24 34 58 8.3 DSE0830F02 8.3 37 42 79

Work materials First High- High- Surface speed Series φ0.500 - φ0.750 - φ1.062 - φ1.312 - 4.5 DSE0450F02 4.5 24 34 58 8.4 DSE0840F02 8.4 37 42 79

choice feed speed Breakage Wear Vc(SFM) L/D 11

fi nish φ0.687 φ1.00 φ1.250 φ2.00 11 4.6 DSE0460F02 4.6 24 34 58 8.5 DSE0850F02 8.5 37 42 79

Low carbon steels(C<3) DS DW DW 2D,3D .001 - .005 .002 - .004 .002 - .004 .002 - .004 DSE0470F02 4.7 24 34 58 8.6 DSE0860F02 8.6 40 44 84

JIS 525-1050 4D,5D .001 - .002 .002 - .004 .002 - .004 4.7

SS400,SM490,S25C,etc. AH725 AH725 AH120 .002 - .004

Carbon steels(C<3) DJ DW DS DW DJ DW 250-800 2D,3D .002 - .005 .002 - .006 .002 - .006 .003 - .007 4.8 DSE0480F02 4.8 26 36 62 8.7 DSE0870F02 8.7 40 44 84

JIS S45C,S55C,etc. AH725 AH725 AH120 AH725 T1015 AH740 4D,5D .002 - .003 .002 - .004 .002 - .005 .003 - .006 4.9 DSE0490F02 4.9 26 36 62 8.8 DSE0880F02 8.8 40 44 84

Low alloy steels DS DW DW 2D,3D .002 - .003 .002 - .005 .002 - .005 .002 - .006 5.0 DSE0500F02 5.0 26 36 62 8.9 DSE0890F02 8.9 40 44 84

JIS SCM415,etc. AH725 AH725 AH725 525-800 4D,5D .002 - .003 .002 - .005 .002 - .005 .002 - .006 Drilling Tools Drilling Tools

Alloy steels DJ DW DS DW DJ DW 250-650 2D,3D .002 - .005 .002 - .006 .002 - .006 .003 - .007 5.1 DSE0510F02 5.1 26 36 62 9.0 DSE0900F02 9.0 40 44 84

JIS SCM440,SCr420,etc. AH725 AH725 AH120 AH725 T1015 AH725 4D,5D .002 - .003 .002 - .004 .002 - .005 .003 - .006 5.2 DSE0520F02 5.2 26 36 62 9.1 DSE0910F02 9.1 40 44 84

Stainless steels DS DS DW 2D,3D .001 - .003 .002 - .004 .002 - .005 .002 - .005

Austenitic 325-650 5.3 DSE0530F02 5.3 26 36 62 9.2 DSE0920F02 9.2 40 44 84

JIS SUS304,SUS316,etc. AH725 AH725 AH120 4D,5D .001 - .003 .002 - .004 .002 - .005 .002 - .005 DSE0540F02 5.4 28 38 66 9.3 DSE0930F02 9.3 40 44 84

Stainless steels DS DS DW 2D,3D .001 - .003 .002 - .004 .002 - .005 .002 - .005 5.4

Martensitic and ferritic 325-725 .002 - .005 5.5 DSE0550F02 5.5 28 38 66 9.4 DSE0940F02 9.4 40 44 84

JIS SUS430,SUS416,etc. AH725 AH725 AH120 4D,5D .001 - .003 .002 - .004 .002 - .005

Stainless steels DS DS DW 2D,3D .002 - .003 .002 - .003 .002 - .004 .002 - .004 5.6 DSE0560F02 5.6 28 38 66 9.5 DSE0950F02 9.5 40 44 84

Precipitation hardening 250-400

JIS SUS630,etc. AH725 AH725 AH120 4D,5D .002 - .003 .002 - .003 .002 - .004 .002 - .004 5.7 DSE0570F02 5.7 28 38 66 9.6 DSE0960F02 9.6 43 46 89

Gray cast irons DJ DJ DJ DW 250-800 2D,3D .002 - .005 .002 - .006 .002 - .007 .003 - .008

JIS FC250,etc. T1015 AH725 AH725 AH740 4D,5D .002 - .004 .002 - .005 .002 - .006 .003 - .006 5.8 DSE0580F02 5.8 28 38 66 9.7 DSE0970F02 9.7 43 46 89

Ductile cast irons DJ DJ DJ DW 2D,3D .002 - .005 .002 - .006 .002 - .007 .003 - .008 5.9 DSE0590F02 5.9 28 38 66 9.8 DSE0980F02 9.8 43 46 89

JIS FCD700,etc. T1015 AH725 AH725 AH740 250-650 4D,5D .002 - .004 .002 - .005 .002 - .006 .003 - .006 6.0 DSE0600F02 6.0 28 38 66 9.9 DSE0990F02 9.9 43 46 89

Aluminum alloys DW .006 - .008 .006 - .010

JIS A2017,ADC12,etc. AH725 650-1300 2D,3D .004 - .006 .006 -.008 .005 - .008 6.1 DSE0610F02 6.1 31 39 70 10.0 DSE1000F02 10.0 43 46 89

4D,5D .003 - .005 .005 - .006 .005 - .006

DS

Super Alloys AH120 100-200 2D,3D .002 - .004 .002 - .004 .002 - .005 .002 - .006 6.2 DSE0620F02 6.2 31 39 70 10.1 DSE1010F02 10.1 43 46 89

.002 - .005

4D,5D .002 - .004 .002 - .004 .002 - .004

DS 2D,3D .002 - .004 .002 - .004 .002 - .004 .002 - .004 6.3 DSE0630F02 6.3 31 39 70 10.2 DSE1020F02 10.2 43 46 89

Titanium 100-200 6.4 DSE0640F02 6.4 31 39 70 10.3 DSE1030F02 10.3 43 46 89

AH120 4D,5D .002 - .004 .005 - .004 .002 - .003 .002 - .003

• When using the smaller side of the diameter range, the feed rate • For high feed machining, apply a feed rate that is approximately 1.5 6.5 DSE0650F02 6.5 31 39 70 10.4 DSE1040F02 10.4 43 46 89

should be set lower. times the standard feed conditions. 6.6 DSE0660F02 6.6 31 39 70 10.5 DSE1050F02 10.5 43 46 89

• For work materials of 40 HRC, the feed rate should be set below • High speed machining means cutting speeds over 150 m/min.

50%. • When using DW insert for troubleshooting, use it within the range of 6.7 DSE0670F02 6.7 31 39 70 10.6 DSE1060F02 10.6 43 46 89

• For difficult-to-cut materials (heat-resistant alloys, etc.), the cutting standard cutting conditions. 6.8

speed should be set 25% below that of carbon steels. DSE0680F02 6.8 34 40 74 10.7 DSE1070F02 10.7 47 48 95

d : Stocked items. d : Stocked items.

: Will be replaced by new products. Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Regrinding

Relating Technical reference 11–16 11–28 Relating Cutting Conditions Procedures Technical reference

(15-1)

(11-31)

pages

(15-1)

pages

(11-85)

Reference pages of Symbols of stock Table of standard cutting conditions

relating items status

Icons overview

j Icons showing drill shapes

d Drill diameter range d Type of coating d Approximate tolerance obtained in drilling

Diameter (Ti,A R )N TiN IT9~10

ø3.0~20.0mm Coated Coated IT class

d Helix angle d Point angle d L / D d Coolant supply method

30° 140° 3

Internal

Helix Point angle L/D Coolant External

Coolant

j Ordering information

d When ordering TAC drill, please specify Cat. No. and quantity.

Example: TDX160W20-2 1 piece.

• Standard packing quantity is 1 piece.

• Inserts must be ordered separately.

d When ordering TAC inserts for TAC drill, please specify Cat. No., grade, and quantity.

Example: XPMT050204R-DJ AH725 10 pieces.

• Standard packing quantity is 10 pieces.

d When ordering solid or brazed drill, please specify Cat. No. and quantity.

Example: DSE0700F02 1 piece.

• Standard packing quantity is 1 piece.