Page 811 - Tungaloy Catalog

P. 811

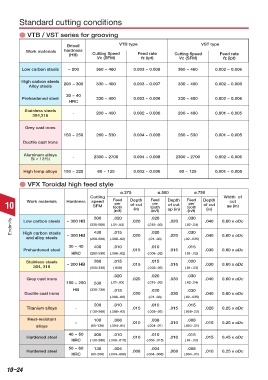

Standard cutting conditions

● VTB / VST series for grooving

Brinell VTB type VST type

Work materials hardness

(HB) Cutting Speed Feed rate Cutting Speed Feed rate

Vc (SFM) fz (ipt) Vc (SFM) fz (ipt)

Low carbon steels ~ 200 360 ~ 460 0.003 ~ 0.008 360 ~ 460 0.002 ~ 0.006

High carbon steels

Alloy steels 200 ~ 300 330 ~ 400 0.003 ~ 0.007 330 ~ 400 0.002 ~ 0.006

30 ~ 40

Prehardened steel 330 ~ 400 0.003 ~ 0.006 330 ~ 400 0.002 ~ 0.006

HRC

Stainless steels - 200 ~ 400 0.002 ~ 0.006 200 ~ 400 0.001 ~ 0.005

304,316

Grey cast irons

150 ~ 250 260 ~ 530 0.004 ~ 0.008 260 ~ 530 0.001 ~ 0.005

Ductile cast irons

Aluminum alloys - 2300 ~ 2700 0.004 ~ 0.008 2300 ~ 2700 0.002 ~ 0.006

Si < 13%)

High temp alloys 150 ~ 225 60 ~ 125 0.002 ~ 0.006 60 ~ 125 0.001 ~ 0.005

● VFX Toroidal high feed style

ø.375 ø.500 ø.750

Cutting Feed Depth Feed Depth Feed Depth Width of

cut

10 Work materials Hardness speed tooth of cut tooth of cut tooth of cut ae (in)

per

per

per

SFM

(in/t) (in) (in/t) ap (in) (in/t) (in)

500 .020 .020 .020 .020 .030 .040 0.60 x øDc

Endmills (330-660) (.01-.03) (.015-.03) (.02-.04)

~ 300 HB

Low carbon steels

.015

.030

430

.020

High carbon steels

and alloy steels ~ 300 HB (260-600) (.008-.02) .020 (.01-.03) .020 (.02-.035) .040 0.60 x øDc

30 ~ 40 400 .010 .010 .015

Prehardened steel .015 .015 .030 0.60 x øDc

HRC (280-530) (.008-.02) (.008-.02) (.01-.02)

Stainless steels ~ 200 HB 260 .015 .015 .015 .015 .020 .030 0.60 x øDc

304, 316 (200-330) (.008) (.008-.02) (.01-.03)

.020 .020 .030

Grey cast irons .020 .030 .040 0.60 x øDc

150 ~ 250 530 (.01-.03) (.015-.03) (.02-.04)

HB (330-730) .015 .020 .030

Ductile cast irons .020 .030 .040 0.60 x øDc

(.008-.02) (.01-.03) (.02-.035)

200 .010 .010 .015

Titanium alloys - .015 .015 .020 0.25 x øDc

(130-260) (.008-.02) (.008-.02) (.008-.02)

Heat-resistant 100 .008 .008 .008

- .010 .010 .015 0.25 x øDc

alloys (65-130) (.004-.01) (.004-.01) (.004-.01)

40 ~ 50 200 .010 .010 .015

Hardened steel .010 .010 .015 0.45 x øDc

HRC (130-260) (.008-.015) (.008-.015) (.01-.02)

50 ~ 60 130 .004 .004 .008

Hardened steel .008 .008 .010 0.25 x øDc

HRC (65-200) (.004-.008) (.004-.008) (.004-.01)

10–24 Relating Cutting Conditions Technical reference

pages

(10-23)

(14-1)