Page 808 - Tungaloy Catalog

P. 808

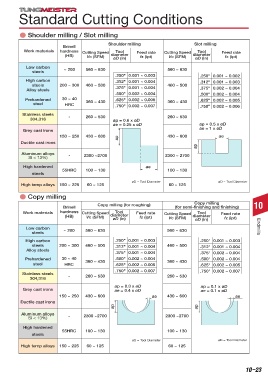

Standard Cutting Conditions

● Shoulder milling / Slot milling

Shoulder milling Slot milling

Brinell

Work materials hardness Cutting Speed Tool Feed rate Cutting Speed Tool Feed rate

(HB) Vc (SFM) diameter fz (ipt) Vc (SFM) diameter fz (ipt)

øD (in)

øD (in)

Low carbon

steels ~ 200 560 ~ 630 560 ~ 630

.250" 0.001 ~ 0.003 .250" 0.001 ~ 0.002

High carbon .312" 0.001 ~ 0.004 .312" 0.001 ~ 0.003

steels 200 ~ 300 460 ~ 500 460 ~ 500

Alloy steels .375" 0.001 ~ 0.004 .375" 0.002 ~ 0.004

.500" 0.002 ~ 0.004 .500" 0.002 ~ 0.004

Prehardened 30 ~ 40 360 ~ 430 .625" 0.002 ~ 0.005 360 ~ 430 .625" 0.002 ~ 0.005

steel HRC .750" 0.002 ~ 0.007 .750" 0.002 ~ 0.006

Stainless steels - 260 ~ 530 260 ~ 530

304,316 ap = 0.6 x øD

ae = 0.25 x øD ap = 0.5 x øD

Grey cast irons ae = 1 x øD

150 ~ 250 430 ~ 600 ap 430 ~ 600 ae

Ductile cast irons

ap

Aluminum alloys - 2300 ~2700 2300 ~ 2700

Si < 13%)

High hardened ae

55HRC 100 ~ 130 100 ~ 130

steels

øD = Tool Diameter øD = Tool Diameter

High temp alloys 150 ~ 225 60 ~ 125 60 ~ 125

● Copy milling

Copy milling (for roughing) Copy milling 10

Brinell (for semi-finishing and finishing)

Work materials hardness Cutting Speed Tool Feed rate Cutting Speed Tool Feed rate

(HB) Vc (SFM) diameter fz (ipt) Vc (SFM) diameter fz (ipt)

øD (in)

øD (in)

Low carbon ~ 200 560 ~ 630 560 ~ 630 Endmills

steels

High carbon .250" 0.001 ~ 0.003 .250" 0.001 ~ 0.003

steels 200 ~ 300 460 ~ 500 .312" 0.001 ~ 0.004 460 ~ 500 .312" 0.001 ~ 0.004

Alloy steels

.375" 0.001 ~ 0.004 .375" 0.002 ~ 0.004

Prehardened 30 ~ 40 .500" 0.002 ~ 0.004 .500" 0.002 ~ 0.004

steel HRC 360 ~ 430 .625" 0.002 ~ 0.005 360 ~ 430 .625" 0.002 ~ 0.005

.750" 0.002 ~ 0.007 .750" 0.002 ~ 0.007

Stainless steels - 260 ~ 530 260 ~ 530

304,316

ap = 0.3 x øD ap = 0.1 x øD

Grey cast irons ae = 0.4 x øD ae = 0.1 x øD

150 ~ 250 430 ~ 600 ae 430 ~ 600 ae

Ductile cast irons

ap ap

Aluminum alloys - 2300 ~2700 2300 ~2700

Si < 13%)

High hardened

55HRC 100 ~ 130 100 ~ 130

steels

øD = Tool Diameter øD = Tool Diameter

High temp alloys 150 ~ 225 60 ~ 125 60 ~ 125

10–23