Page 810 - Tungaloy Catalog

P. 810

Installation Notes & Examples

Note

● Do not apply the lubricant to the threaded connection.

● Please use the proper wrench according to the cutting head. The

wrench should be ordered separately.

Gap

● Too much torque may cause head breakage.

● When highly accurate machining is required the carbide shank is

recommended.

Practical Examples

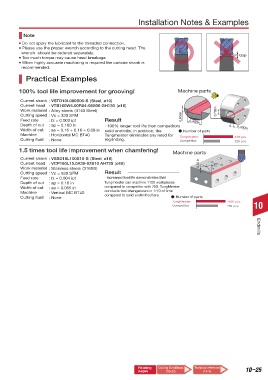

100% tool life improvement for grooving! Machine parts

Current shank : VSTD10L080S06-S (Steel, ø10)

Current head : VTB160W4.00R04-06S06 GH130 (ø16)

Work material : Alloy steels (4140 Steel) 0.709in

Cutting speed : Vc = 330 SFM 0.906in

Feed rate : fz = 0.003 ipt Result 0.400in

Depth of cut : ap = 0.100 in · 100% longer tool life than competitors 0.400in

Width of cut : ae = 0.16 + 0.16 + 0.08 in solid endmills. In addition, the ● Number of parts

Machine : Horizontal MC BT40 Tungmeister eliminates any need for

TungMeister 420 pcs.

Cutting fluid : None regrinding. Competitor 220 pcs.

1.5 times tool life improvement when chamfering!

Machine parts

Current shank : VSSD16L100S10-S (Steel, ø16)

Current head : VCP160L15.0A30-02S10 AH725 (ø16) 0.10 in 30°

Work material : Stainless steels (316SS)

Cutting speed : Vc = 530 SFM Result

Feed rate : fz = 0.004 ipt · Increased tool life demonstrates that

Depth of cut : ap = 0.10 in Tungmeister can machine 1100 workpieces

Width of cut : ae = 0.055 in compared to competitor with 750. TungMeister

Machine : Vertical MC BT40 conducts tool changeovers in 1/10 of time

Cutting fluid : None compared to solid endmill cutters. ● Number of parts

TungMeister 1100 pcs.

Competitor 750 pcs. 10

Endmills

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Relating Cutting Conditions Technical reference 10–25

pages (10-23) (14-1)