Roemheld Body Clamping Modules

7250 psi maxSingle and Double Acting

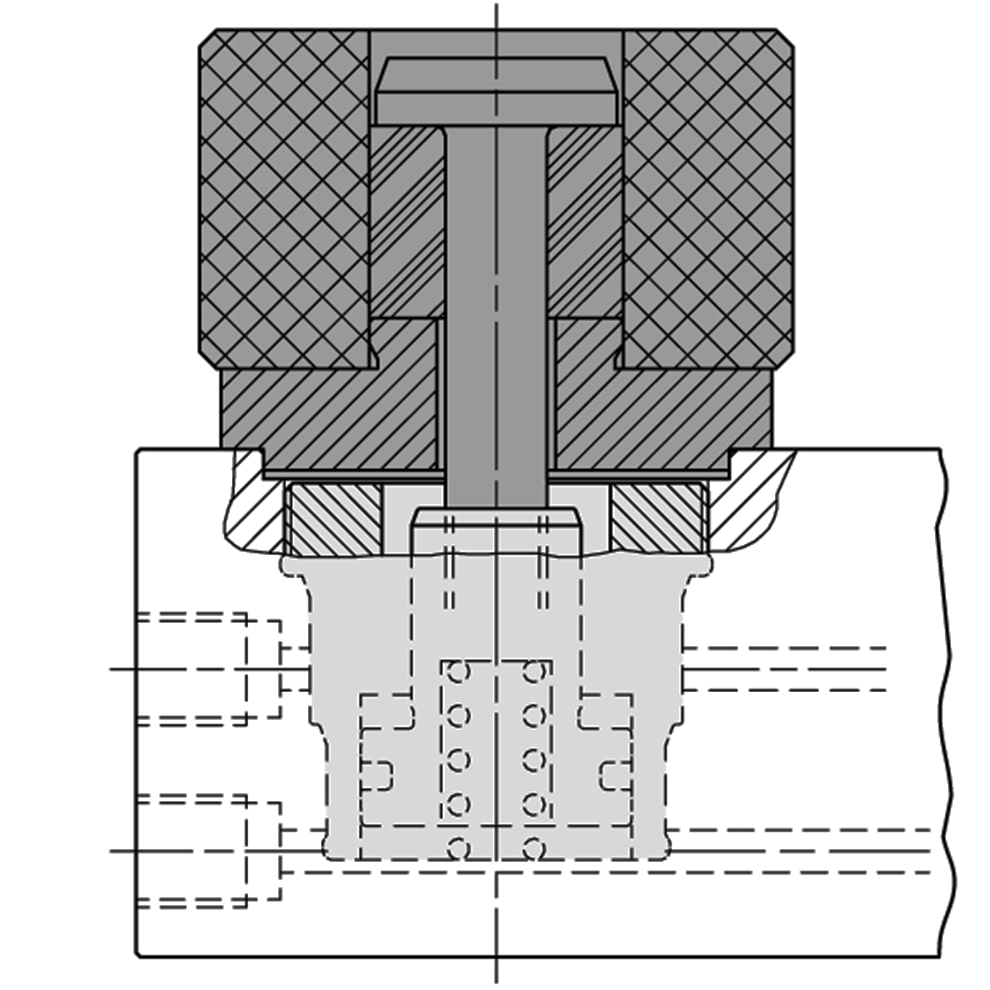

These pull clamps can be used to make a combination locator and internal clamp by adding a custom locating pin. Installation steps include machining a 55mm counterbored hole to be used as a reference diameter to accept custom locators. The plunger has an extended key at the bottom to act as an anti-rotation device, for applications where plunger orientation is important to provide machining clearance. These versatile clamping modules provide considerable force in a small size, and can be placed very close together. Manifold mounting allows an extremely compact, space-saving design.

Application Information

The plunger has an extended key at the bottom to act as an anti-rotation device, for applications where plunger orientation is important to provide machining clearance.

Clamping Action

Applying fluid pressure pushes the piston down, pulling down a drawbar inserted in the center hole. Spring return (single acting), with the option to add a return pressure line to use as double acting.

Mounting & Fluid Supply

Clamp should be recessed into the fixture as shown in the installation drawings. Carefully follow hole-preparation instructions in the drawings. The overall depth of the bored hole must be strictly observed, because the bottom acts as a stop (to make the short length of this unit possible). The insertion chamfer and the entrances of the fluid passages into the bored hole must be rounded to avoid damaging the seals during clamp installation.

Clamping with a C Washer

Clamping can be accomplished using a drawbar and C Washer. This method provides maximum clamping force, but has some disadvantages. The C Washer is a loose part that must be handled each time a workpiece is loaded. Also, the C Washer can interfere with machining operations on the top side of the workpiece.

Clamping with a Polyurethane Spring

Clamping can also be accomplished using a drawbar to compress a polyurethane spring that is slightly smaller than the inside diameter, to apply clamping force from the inside. Note: this method still requires a locating pin to provide location for the inside diameter. Clamping force depends entirely on the spring Material, with the plunger going through its full 6mm stroke.

Material

| Item | Material | Heat Treat | Finish |

| Body | Steel | - | Black Oxide |

| Plunger | Steel | - | Black Oxide |

Parts Specification

| Maximum Clamping Force (lbs) | Maximum Clamping Force (kn) | Centerhole Thread X Depth | Locating Diameter (mm) | External Thread | Body Height (mm) | Clamping Stroke (mm) |

| 5500 lbs. | 24.5 kN | M12 x 14mm | 55mm | M50 x 1.5 | 44.5mm | 6mm |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

844.548.0100

844.548.0100

Quotes

Quotes

Quick Order

Quick Order