The Essential Tools Every Beginner Machinist Needs

Mar 12, 2019

Every machinist needs the proper tools in order to do their job right. When you're just starting out, making sure that you have every single tool on the list can be a bit overwhelming. Luckily, an experienced industrial tool company will have everything that you need to properly stock your tool set. Learn which essential tools a beginner machinist needs and start your journey into machining the right way.

- Calipers: A pair of pocket calipers needs to be in every machinist's tool kit. They are what you use to measure the distance between two opposing ends of an object. The best caliper brand depends on the machinist you're talking to, but they come in two main forms today: dial and digital.

- Turning machines: Otherwise known as an engine lathe, the metal-turning machine is one of the most important of all machine tools. This is because the engine lathe can be used for a wide range of facing, turning, and drilling operations. When using an engine lathe, there are a few guidelines with which you should be familiar. For instance, the correct tension in a lathe should have a deflection of about 3/8 of an inch in each belt. Know these types of guidelines and you'll be using your engine lathe correctly.

- Set of starter end mills: A set of end mills is what makes every machining operation possible. The best sets will come in a variety of shapes and sizes and be made in solid carbide for extra durability.

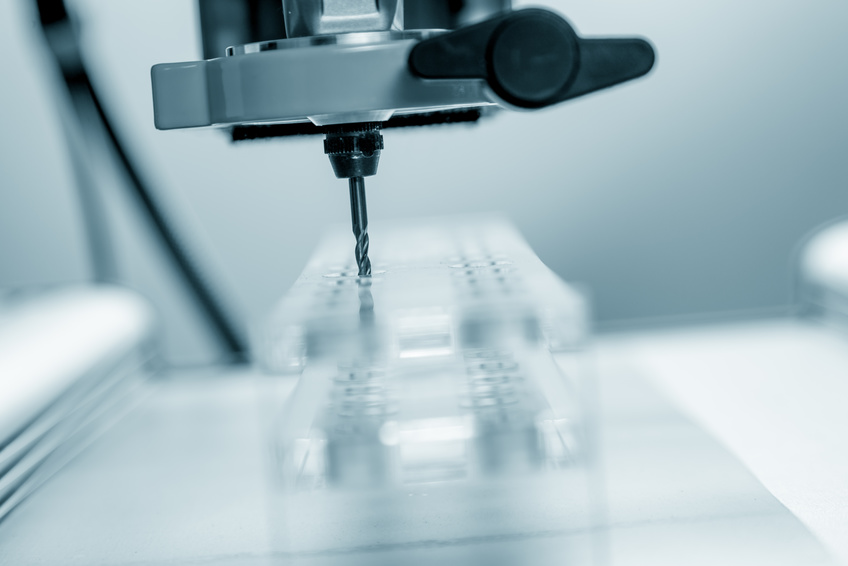

- Milling machines: A milling machine cuts the metal of a workpiece as you feed it against the machine's rotating cutting tool, also known as a milling cutter. Milling machines can cut almost anything, including flat surfaces, shoulders, grooves, dovetails, inclined surfaces, and T-slots. Each of these operations would require a milling cutter in a specific shape and size from an industrial tool company.

- Shapers and planers: While they differ slightly, both shaping and planing operations involve machining flat surfaces, grooves, T-slots, and angular surfaces with single-point tools. Shapers can only machine parts as large as 36 inches, but some planing machines can machine parts up to 50 feet long.

The first step to diving into the world of machining is having the right tools. Whether you find yourself needing a drill chuck sleeve, mill power feed, or anything in between, turn to All Industrial Tool Supply, the trusted industrial tool company.

714.897.1700

714.897.1700

Chat

Chat

Email

Email

844.548.0100

844.548.0100

Quotes

Quotes

Quick Order

Quick Order