Page 107 - All Industrial Tool Supply | General Catalog

P. 107

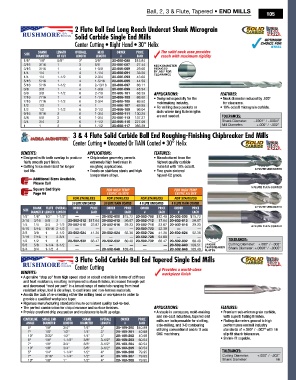

Ball, 2, 3 & Flute, Tapered • END MILLS

105

2 Flute Ball end long reach undercut Shank micrograin

Solid carbide Single end mills

Center Cutting • Right Hand • 30° Helix

Shank length overall neck order Price The solid neck area provides

Size

diameter oF cut length length # each reach with maximum rigidity

1/8" 1/8" 5/8" 2" 3/8" 20-606-085 $15.84

3/16 3/16 1 3 5/8 20-606-087 27.44 NEck DIaMEtEr

3/16 3/16 1 4 1-5/8 20-606-089 29.66 rEDucED

1/4 1/4 1 4 1-1/4 20-606-091 33.56 by .020" for

cLEaraNcE

1/4 1/4 1-1/2 6 2-3/4 20-606-093 43.60

5/16 5/16 1 4 1-5/16 20-606-095 44.59

5/16 5/16 1-1/2 6 2-13/16 20-606-097 66.11

3/8 3/8 1 4 1-3/8 20-606-099 48.94

3/8 3/8 1-1/2 6 2-7/8 20-606-101 68.39 APPLICATIONS: FeATureS:

7/16 7/16 1 4 1-1/4 20-606-103 68.85 • Designed especially for the • Neck diameter reduced by .020"

7/16 7/16 1-1/2 6 2-3/4 20-606-105 89.50 moldmaking industry. for clearance.

1/2 1/2 1 4 1 20-606-107 69.95 • For milling deep pockets or • 10% cobalt micrograin carbide.

1/2 1/2 1-1/2 6 2-1/2 20-606-109 99.04 slots where long flute lengths

9/16 9/16 2 6 1-3/4 20-606-111 130.25

5/8 5/8 2 6 1-3/4 20-606-113 137.27 are not needed. toleranceS:

3/4 3/4 2 6 1-1/2 20-606-115 227.09 Shank Diameter: -.0001" / -.0004"

1 1 2 6 1-1/2 20-606-117 386.38 Mill Diameter: +.000" / -.002"

3 & 4 Flute Solid carbide Ball end roughing-Finishing chipbreaker end mills

Center Cutting • Uncoated Or TiAlN Coated • 30° Helix

BeNeFITS: APPLICATIONS: FeATureS:

• Designed with tooth overlap to produce • Chipbreaker geometry permits • Manufactured from the

fairly smooth part finish. extremely high feed rates in highest quality carbide

• Cutting force minimized for longer roughing applications. material with 10% cobalt.

tool life. • Excels on stainless steels and high • Fine grain-sintered 3 fLutE uNcoatED

temperature alloys. hipped-C2 grade.

Additional Sizes Available,

Please Call

Square End Style For HigH Temp For HigH Temp

3 fLutE tialN coatED

Page 94 exoTic Alloys exoTic Alloys

For sTAinless For sTAinless For sTAinless For sTAinless

3 Flute uncoated 3 Flute tialn coated 4 Flute uncoated 4 Flute tialn coated

Shank Flute overall order Price order Price order Price order Price 4 fLutE uNcoatED

Size

diameter length length # each # each # each # each

1/8" 1/8" 1/2" 1-1/2" — — 20-502-608 $15.72 20-502-708 $12.49 20-502-808 $15.72

3/16 3/16 5/8 2 20-502-512 $17.64 20-502-612 20.87 20-502-712 17.64 20-502-812 20.87

1/4 1/4 3/4 2-1/2 20-502-516 23.87 20-502-616 29.23 20-502-716 23.87 20-502-816 29.23 4 fLutE tialN coatED

5/16 5/16 13/16 2-1/2 — — — — 20-502-720 32.38 — —

3/8 3/8 1 2-1/2 20-502-524 41.36 20-502-624 52.36 20-502-724 41.36 20-502-824 52.36

7/16 7/16 1 2-3/4 — — — — 20-502-728 54.89 — —

1/2 1/2 1 3 20-502-532 66.47 20-502-632 80.40 20-502-732 66.47 20-502-832 80.40 toleranceS:

5/8 5/8 1-1/4 3-1/2 — — — — — — 20-502-840 109.51 uNIquE Cutting Diameter: +.000" / -.002"

3/4 3/4 1-1/2 4 — — 20-502-648 169.49 — — 20-502-848 169.49 chIpbrEakEr Shank Diameter: +.0000" / -.0005"

fLutES

3 Flute Solid carbide Ball end tapered Single end mills

Center Cutting Provides a world-class

BeNeFITS: workpiece finish

• A genuine “step up” from high speed steel or cobalt end mills in terms of stiffness

and heat resistance, resulting in improved surface finishes, increased through-put

and decreased “cost per part” in a broad range of materials ranging from heat

resistant alloys, tool & die alloys, to cast irons and non-ferrous materials.

• Avoids the task of re-orienting either the milling head or workpiece in order to

provide a qualified workpiece taper.

• Rigorous manufacturing standards insure consistent quality tool-to-tool.

• The perfect combination for chip clearance and surface finishes. APPLICATIONS: FeATureS:

• Provide excellent chip evacuation and resistance to built up edge. • A staple in aerospace, mold-making • Premium sub-micron grain carbide,

and die-cast industries, tapered end with superb fluting finishes.

centerline Small end Flute Shank overall order Price mills are indispensable for slotting, • Fluting diameters ground to high

angle diameter length diameter length # each side-milling, and 3-D contouring performance endmill industry

5º 1/8" 3/4" 1/4" 3" 20-109-200 $40.88 utilizing conventional and/or 5 axis standards of +.000" / -.002" with h6

7º 1/8" 1/2" 1/4" 3" 20-109-201 40.88 CNC machinery. slip-fit shank tolerances.

10º 3/32" 1/2" 1/4" 3" 20-109-202 40.88

5º 1/8" 1-1/2" 3/8" 3-1/2" 20-109-203 60.54 • Shrink-fit capable.

7º 1/8" 3/4" 3/8" 3-1/2" 20-109-204 60.54

10º 1/8" 3/4" 3/8" 3-1/2" 20-109-205 60.54

5º 1/4" 1-1/4" 1/2" 4" 20-109-206 79.95 toleranceS:

7º 3/16" 1-1/4" 1/2" 4" 20-109-207 79.95 Cutting Diameter: +.000" / -.002"

10º 1/8" 1" 1/2" 4" 20-109-208 79.95 Shank Diameter: h6