Page 111 - All Industrial Tool Supply | General Catalog

P. 111

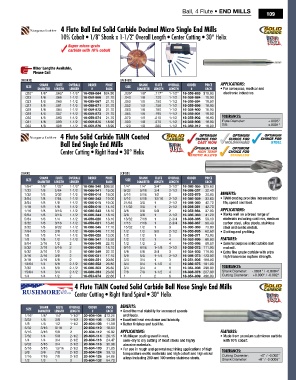

Ball, 4 Flute • END MILLS

109

4 Flute Ball End Solid Carbide Decimal Micro Single End Mills

10% Cobalt • 1/8" Shank x 1-1/2" Overall Length • Center Cutting • 30° Helix

Super micro-grain

carbide with 10% cobalt

Other Lengths Available,

Please Call

[MEB430] [MEB430]

Shank FluTE ovErall orDEr PriCE Shank FluTE ovErall orDEr PriCE APPLICATIONS:

SizE SizE

DiaMETEr lEngTh lEngTh # EaCh DiaMETEr lEngTh lEngTh # EaCh • For aerospace, medical and

.020" 1/8" .060" 1-1/2" 16-059-864 $24.90 .039" 1/8" .117" 1-1/2" 16-059-883 $18.90 electronic industries.

.022 1/8 .066 1-1/2 16-059-866 21.70 .040 1/8 .120 1-1/2 16-059-884 18.90

.023 1/8 .069 1-1/2 16-059-867 21.70 .050 1/8 .150 1-1/2 16-059-894 18.90

.027 1/8 .081 1-1/2 16-059-871 21.70 .052 1/8 .156 1-1/2 16-059-896 18.90

.028 1/8 .084 1-1/2 16-059-872 21.70 .060 1/8 .180 1-1/2 16-059-900 18.90

.029 1/8 .087 1-1/2 16-059-873 21.70 .065 1/8 .195 1-1/2 16-059-901 18.90 TolEranCES:

.030 1/8 .090 1-1/2 16-059-874 21.70 .070 1/8 .210 1-1/2 16-059-902 18.90

.031 1/8 .093 1-1/2 16-059-875 18.90 .090 1/8 .270 1-1/2 16-059-906 18.90 Flute Diameter: ±.0005"

.032 1/8 .096 1-1/2 16-059-876 18.90 .120 1/8 .360 1-1/2 16-059-912 18.90 TIR: ±.0001"

4 Flute Solid Carbide Tialn Coated

Ball End Single End Mills

Center Cutting • Right Hand • 30° Helix

[CB430] [CB430]

Shank FluTE ovErall orDEr PriCE Shank FluTE ovErall orDEr PriCE

SizE SizE

DiaMETEr lEngTh lEngTh # EaCh DiaMETEr lEngTh lEngTh # EaCh

1/64" 1/8" 1/32" 1-1/2" 16-086-340 $36.50 1/4" 1/4" 3/4" 2-1/2" 16-086-355 $25.60

1/32 1/8 5/64 1-1/2 16-086-341 19.00 9/32 5/16 3/4 2-1/2 16-086-357 32.40

1/32 1/8 3/32 1-1/2 16-056-014 19.00 5/16 5/16 1/2 2 16-053-979 30.80 BeNefITS:

3/64 1/8 7/64 1-1/2 16-086-342 19.00 5/16 5/16 13/16 2-1/2 16-086-359 33.60 • TiAlN coating provides increased tool

3/64 1/8 1/8 1-1/2 16-056-015 19.00 21/64 3/8 1 2-1/2 16-086-360 42.70 life, speed and feed.

1/16 1/8 1/8 1-1/2 16-056-016 14.10 11/32 3/8 1 2-1/2 16-086-361 42.70

1/16 1/8 3/16 1-1/2 16-086-343 18.10 3/8 3/8 5/8 2 16-053-984 37.90 APPLICATIONS:

5/64 1/8 3/16 1-1/2 16-086-344 18.10 3/8 3/8 1 2-1/2 16-086-363 41.20 • Works well on a broad range of

5/64 1/8 1/4 1-1/2 16-056-020 18.10 13/32 7/16 1 2-3/4 16-086-365 59.10 materials including cast iron, medium

3/32 1/8 3/16 1-1/2 16-056-021 13.40 7/16 7/16 1 2-3/4 16-086-367 50.40 carbon steel, alloy steels, stainless

3/32 1/8 9/32 1-1/2 16-086-345 17.10 15/32 1/2 1 3 16-086-369 73.00 steel and exotic metals.

7/64 1/8 3/8 1-1/2 16-086-346 17.10 1/2 1/2 5/8 2-1/2 16-053-995 62.60 • Slotting and profiling.

1/8 1/8 1/4 1-1/2 16-056-025 13.00 1/2 1/2 1 3 16-086-371 73.00

1/8 1/8 1/2 1-1/2 16-086-347 15.50 1/2 1/2 1 4 16-053-996 88.80 feATureS:

9/64 3/16 1/2 2 16-086-348 22.70 1/2 1/2 2 4 16-053-998 88.80 • General purpose solid carbide ball

5/32 3/16 5/16 2 16-056-030 18.10 9/16 9/16 1-1/8 3-1/2 16-086-372 111.00 end mill.

5/32 3/16 1/2 2 16-086-349 22.70 5/8 5/8 3/4 3 16-054-002 119.00 • Extra fine grade carbide with ultra

3/16 3/16 3/8 2 16-056-031 17.10 5/8 5/8 1-1/4 3-1/2 16-086-373 123.00 high transverse rupture strength.

3/16 3/16 5/8 2 16-086-351 20.80 3/4 3/4 1 3 16-054-005 168.00

13/64 1/4 5/8 2-1/2 16-086-352 26.80 3/4 3/4 1-1/2 4 16-086-375 181.00

7/32 1/4 5/8 2-1/2 16-086-353 26.80 3/4 3/4 4 6 16-054-008 298.00 TolEranCES:

15/64 1/4 3/4 2-1/2 16-086-354 26.80 7/8 7/8 1-1/2 4 16-086-376 287.00 Shank Diameter: -.0001" / -0.0004"

1/4 1/4 1/2 2 16-053-974 22.60 1 1 2 6 16-054-009 496.00 Cutting Diameter: +0.000" / -0.002"

4 Flute Tialn Coated Solid Carbide Ball nose Single End Mills

Center Cutting • Right Hand Spiral • 30° Helix

Shank FluTE ovErall orDEr PriCE BeNefITS:

SizE

DiaMETEr lEngTh lEngTh # EaCh • Good thermal stability for increased speeds

1/16" 1/8" 1/4" 1-1/2" 20-604-104 $13.25 and feeds.

3/32 1/8 3/8 1-1/2 20-604-106 13.38 • Excellent heat resistance and lubricity.

1/8 1/8 1/2 1-1/2 20-604-108 11.58 • Better finishes and tool life.

5/32 3/16 9/16 2 20-604-110 18.53

3/16 3/16 5/8 2 20-604-112 16.92 APPLICATIONS: feATureS:

7/32 1/4 5/8 2-1/2 20-604-114 26.15 • Multilayer coating used in wet, • Made from premium submicron carbide

1/4 1/4 3/4 2-1/2 20-604-116 24.47 semi-dry to dry cutting of most steels and highly with 10% cobalt.

9/32 5/16 3/4 2-1/2 20-604-118 35.38 abrasive materials.

5/16 5/16 13/16 2-1/2 20-604-120 31.05 • For use in rough and general machining applications of high

3/8 3/8 7/8 2-1/2 20-604-124 39.13 temperature exotic materials and high cobalt and high nickel TolEranCES:

7/16 7/16 7/8 2-1/2 20-604-128 54.06 alloys including 200 and 300 series stainless steels. Cutting Diameter: +0" / -0.002"

1/2 1/2 1 3 20-604-132 64.70 Shank Diameter: +0" / -0.0005"