Page 935 - Ceratizit Catalog

P. 935

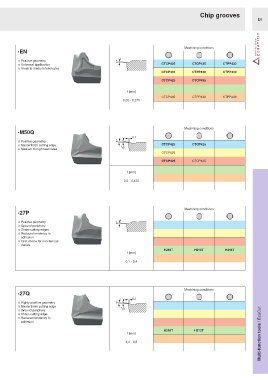

Chip grooves

E8

Machining conditions

-EN

○ Positive geometry 5°

○ Universal application CTCP425 CTCP435 CTPP430

○ Small to medium feed rates

CTCP435 CTPP430 CTPP430

CTCP425 CTCP435

f [mm]

CTCP435 CTPP430 CTPP430

0,05 - 0,275

Machining conditions

-M50Q

0,1

○ Positive geometry 5°

○ Masterfinish cutting edge CTCP425 CTCP425

○ Medium to high feed rates 15°

CTCP425

CTCP425 CTCP425

f [mm]

0,2 - 0,425

Machining conditions

-27P

○ Positive geometry 5°

○ Ground periphery

○ Sharp cutting edges

○ Reduced tendency to

adhesion

○ First choice for non-ferrous

metals

H216T H216T H216T

f [mm]

0,1 - 0,4

Machining conditions

-27Q

0,1

○ Highly positive geometry 5°

○ Masterfinish cutting edge

○ Ground periphery 15°

○ Sharp cutting edge

○ Reduced tendency to

adhesion

H210T H210T

f [mm] Multi-function tools / EcoCut

0,2 - 0,5