Page 937 - Ceratizit Catalog

P. 937

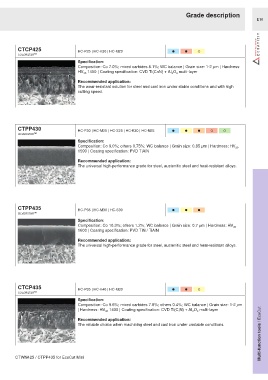

Grade description

E10

CTCP425 HC-P25 | HC-K30 | HC-M20 ● ● ○

COLORSTAR TM

Specification:

Composition: Co 7.0%; mixed carbides 8.1%; WC balance | Grain size: 1-2 µm | Hardness:

HV 1450 | Coating specification: CVD Ti(CnN) + AI O multi-layer

30

2

3

Recommended application:

The wear-resistant solution for steel and cast iron under stable conditions and with high

cutting speed.

CTPP430

HC-P30 | HC-M25 | HC-S25 | HC-K30 | HC-N25 ● ● ● ○ ○

SILVERSTAR TM

Specification:

Composition: Co 9.0%; others 0.75%; WC balance | Grain size: 0.85 µm | Hardness: HV

30

1590 | Coating specification: PVD TiAlN

Recommended application:

The universal high-performance grade for steel, austenitic steel and heat-resistant alloys.

CTPP435 HC-P35 | HC-M30 | HC-S30 ● ● ●

SILVERSTAR TM

Specification:

Composition: Co 10.3%; others 1.2%; WC balance | Grain size: 0.7 µm | Hardness: HV

30

1600 | Coating specification: PVD TiN / TiAlN

Recommended application:

The universal high-performance grade for steel, austenitic steel and heat-resistant alloys.

CTCP435 HC-P35 | HC-K40 | HC-M30 ● ● ○

TM

COLORSTAR

Specification:

Composition: Co 9.6%; mixed carbides 7.8%; others 0.4%; WC balance | Grain size: 1-2 µm

Multi-function tools / EcoCut

| Hardness: HV 1400 | Coating specification: CVD Ti(C,N) + AI O multi-layer

3

2

30

Recommended application:

The reliable choice when machining steel and cast iron under unstable conditions.

CTWN425 / CTPP435 for EcoCut Mini